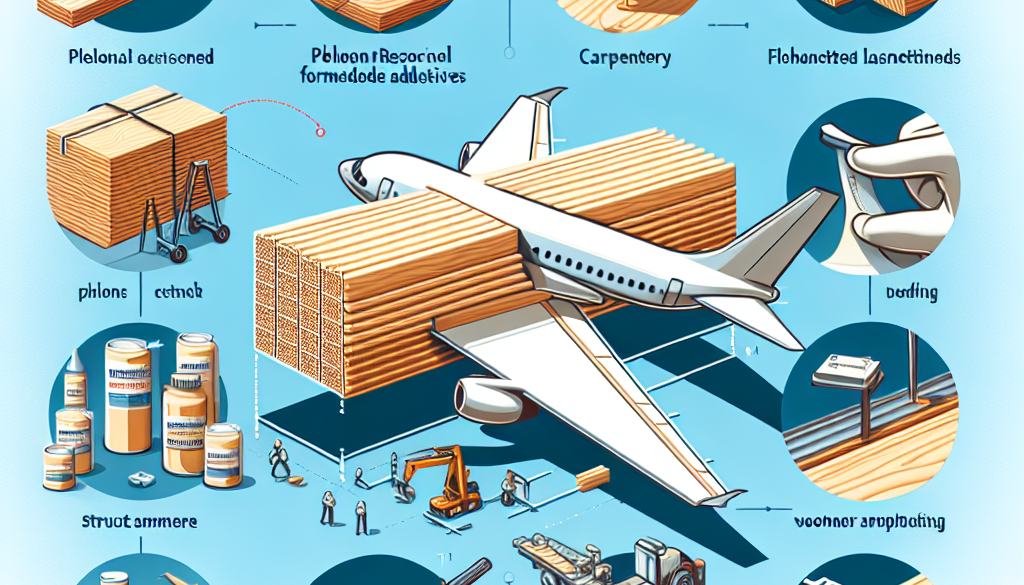

Phenol Resorcinol Formaldehyde Adhesives: Uses

-

Table of Contents

Phenol Resorcinol Formaldehyde Adhesives: Versatile Applications and Benefits

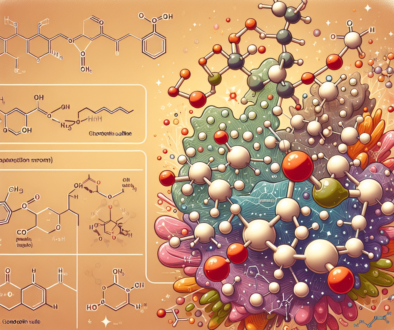

Phenol Resorcinol Formaldehyde (PRF) adhesives are a class of synthetic polymers widely recognized for their exceptional bonding strength and durability. These adhesives are formed by the polymerization of phenol, resorcinol, and formaldehyde, and are known for their resistance to heat, chemicals, and weathering. PRF adhesives have become indispensable in various industries due to their robust performance under extreme conditions. This article delves into the uses of PRF adhesives, highlighting their applications, advantages, and the industries that rely on them.

Understanding PRF Adhesives

PRF adhesives are thermosetting polymers that, once cured, create strong, irreversible bonds. They are characterized by their dark color and are typically used in applications where the bond must withstand severe environments. The unique chemistry of PRF adhesives allows them to maintain their adhesive properties in the presence of moisture, high temperatures, and other challenging conditions.

Key Industries and Applications

The versatility of PRF adhesives is evident in their widespread use across various sectors. Here are some of the key industries and applications:

- Woodworking and Construction: PRF adhesives are extensively used in the manufacture of laminated veneer lumber (LVL), plywood, and other engineered wood products. They are preferred for their ability to create strong bonds that can withstand the rigors of construction and outdoor exposure.

- Aerospace and Automotive: The aerospace and automotive industries utilize PRF adhesives for bonding metal, composite, and plastic components. Their high-temperature resistance makes them suitable for applications near engines or other heat-generating parts.

- Marine: In boat building and repair, PRF adhesives are chosen for their water-resistant properties, ensuring the integrity of hulls and other structural components in marine environments.

- Electrical Engineering: PRF adhesives are used in the electrical industry to bond and insulate components due to their excellent dielectric properties and resistance to electrical currents.

Advantages of PRF Adhesives

PRF adhesives offer several advantages that make them a preferred choice for demanding applications:

- High Bond Strength: PRF adhesives form bonds that are stronger than the materials they are joining, ensuring structural integrity.

- Thermal Resistance: They can withstand high temperatures without losing their adhesive properties, making them ideal for heat-exposed applications.

- Chemical and Weather Resistance: PRF adhesives are resistant to chemicals, solvents, and the elements, which is crucial for outdoor and marine applications.

- Longevity: The durability of PRF adhesives means that they can provide long-lasting bonds, reducing the need for maintenance and repairs.

Case Studies and Statistics

Real-world applications of PRF adhesives demonstrate their effectiveness:

- In the construction of the 2012 London Olympic Velodrome, PRF adhesives were used to bond the wooden track, ensuring a durable and reliable surface for competitive cycling.

- According to a market analysis by Grand View Research, the global wood adhesive market size was valued at USD 4.23 billion in 2018, with PRF adhesives playing a significant role due to their superior performance in wood bonding applications.

Conclusion

Phenol Resorcinol Formaldehyde adhesives are a critical component in various industries, offering unmatched strength, durability, and resistance to harsh conditions. Their use in woodworking, aerospace, automotive, marine, and electrical engineering underscores their versatility and reliability. As technology advances, the demand for PRF adhesives is likely to grow, further cementing their status as a go-to solution for high-performance bonding needs.

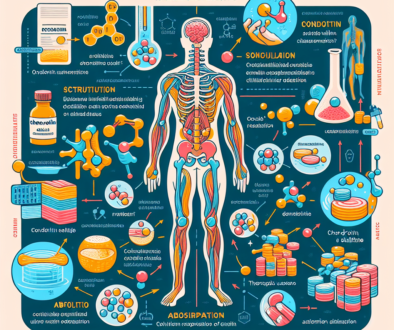

Discover ETchem’s Protein Products

While PRF adhesives serve the needs of industries requiring strong, durable bonds, ETchem offers a different kind of essential material: high-quality protein products. ETchem’s range of collagen products, including marine, fish, bovine, chicken, and various types of collagen, cater to the nutraceutical, pharmaceutical, cosmeceutical, and food and beverage industries. With a focus on neutral taste and instant solubility, ETchem’s offerings are designed to meet the diverse protein needs of manufacturers and distributors worldwide.

About ETChem:

ETChem, a reputable Chinese Collagen factory manufacturer and supplier, is renowned for producing, stocking, exporting, and delivering the highest quality collagens. They include marine collagen, fish collagen, bovine collagen, chicken collagen, type I collagen, type II collagen and type III collagen etc. Their offerings, characterized by a neutral taste, instant solubility attributes, cater to a diverse range of industries. They serve nutraceutical, pharmaceutical, cosmeceutical, veterinary, as well as food and beverage finished product distributors, traders, and manufacturers across Europe, USA, Canada, Australia, Thailand, Japan, Korea, Brazil, and Chile, among others.

ETChem specialization includes exporting and delivering tailor-made collagen powder and finished collagen nutritional supplements. Their extensive product range covers sectors like Food and Beverage, Sports Nutrition, Weight Management, Dietary Supplements, Health and Wellness Products, ensuring comprehensive solutions to meet all your protein needs.

As a trusted company by leading global food and beverage brands and Fortune 500 companies, ETChem reinforces China’s reputation in the global arena. For more information or to sample their products, please contact them and email karen(at)et-chem.com today.