Oxidation of Resorcinol: Process Explained

-

Table of Contents

- Oxidation of Resorcinol: A Comprehensive Process Overview

- Understanding Resorcinol

- The Oxidation Process of Resorcinol

- Common Oxidizing Agents and Conditions

- Factors Influencing the Oxidation Process

- Applications of Oxidized Resorcinol

- Case Studies and Examples

- Environmental and Safety Considerations

- Advancements in Oxidation Techniques

- Conclusion: Key Takeaways from the Oxidation of Resorcinol

- Discover ETchem’s Protein Products

Oxidation of Resorcinol: A Comprehensive Process Overview

Resorcinol is an important chemical compound with a wide range of applications in the pharmaceutical, cosmetic, and chemical industries. Understanding the oxidation process of resorcinol is crucial for optimizing its use and enhancing the efficiency of production methods. This article delves into the oxidation process of resorcinol, providing valuable insights and detailed explanations.

Understanding Resorcinol

Resorcinol, also known as 1,3-dihydroxybenzene, is a dihydroxybenzene derivative that is structurally related to phenol. It is a white crystalline solid that is soluble in water, alcohol, and ether. Resorcinol is commonly used in the production of resins, dyes, explosives, pharmaceuticals, and various organic compounds. Its unique chemical properties make it a versatile intermediate in synthetic chemistry.

The Oxidation Process of Resorcinol

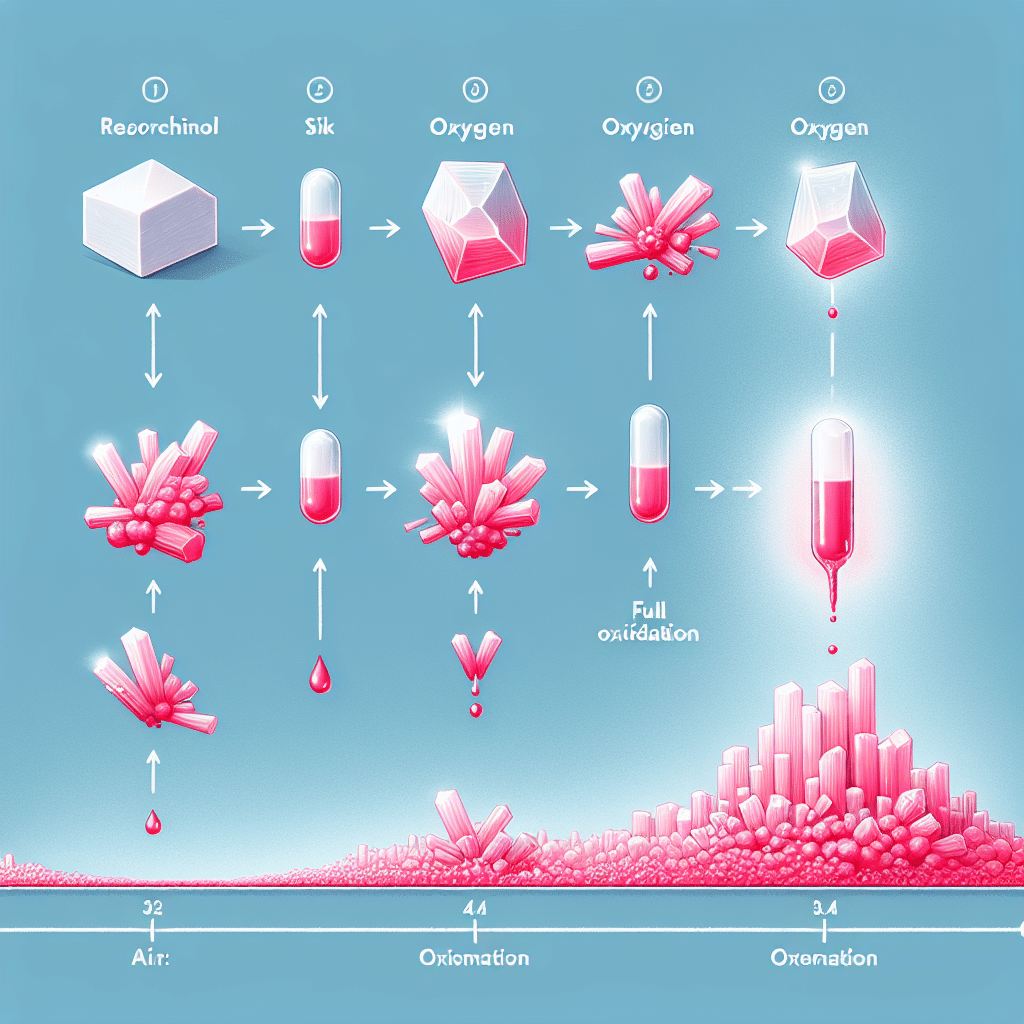

Oxidation is a chemical reaction that involves the transfer of electrons between chemical species. When resorcinol undergoes oxidation, it can form several different products depending on the conditions and reagents used. The oxidation process can be carried out using various oxidizing agents such as hydrogen peroxide, ozone, or metal catalysts.

Common Oxidizing Agents and Conditions

- Hydrogen Peroxide: Often used in aqueous solutions, hydrogen peroxide can oxidize resorcinol to form hydroquinone and quinone derivatives.

- Ozone: Ozone is a powerful oxidizing agent that can react with resorcinol to produce ozonides and other oxygen-rich compounds.

- Metal Catalysts: Transition metals like copper and manganese, often in the form of salts or complexes, can facilitate the oxidation of resorcinol to various products.

Factors Influencing the Oxidation Process

The outcome of the oxidation process is influenced by several factors, including:

- Concentration of the oxidizing agent

- Temperature and pressure conditions

- pH of the reaction medium

- Presence of catalysts or inhibitors

- Reaction time

Applications of Oxidized Resorcinol

The products of resorcinol oxidation have numerous applications across different industries. For example, quinones derived from resorcinol oxidation are used in the synthesis of dyes and pigments. Hydroquinone, another oxidation product, is widely used in photographic development and as a skin-lightening agent in cosmetics.

Case Studies and Examples

One notable case study involves the use of oxidized resorcinol derivatives in the production of high-performance resins. These resins exhibit improved thermal stability and mechanical properties, making them suitable for aerospace and automotive applications.

In the pharmaceutical industry, oxidation products of resorcinol are used to synthesize various active pharmaceutical ingredients (APIs) that have antiseptic, antifungal, and keratolytic properties.

Environmental and Safety Considerations

The oxidation of resorcinol must be conducted with environmental and safety considerations in mind. Proper handling and disposal of chemical reagents and by-products are essential to minimize environmental impact. Additionally, safety protocols must be in place to protect workers from potential hazards associated with the chemicals involved in the oxidation process.

Advancements in Oxidation Techniques

Recent advancements in oxidation techniques have focused on developing greener and more sustainable methods. These include the use of biocatalysts, such as enzymes, and the implementation of solvent-free reactions. Such innovations aim to reduce the environmental footprint of chemical processes and enhance the overall efficiency of resorcinol oxidation.

Conclusion: Key Takeaways from the Oxidation of Resorcinol

The oxidation of resorcinol is a complex process that yields a variety of useful products. Understanding the factors that influence the reaction can lead to improved production methods and applications. The process has significant implications for the pharmaceutical, cosmetic, and chemical industries, among others. As research continues, more sustainable and efficient oxidation methods are likely to emerge, further expanding the potential uses of resorcinol and its derivatives.

Discover ETchem’s Protein Products

For those interested in high-quality protein products, ETchem offers a range of collagen-based solutions. Their extensive product line includes marine, fish, bovine, chicken, type I, II, and III collagens, catering to various industry needs. ETchem’s commitment to quality and customer satisfaction makes them a top choice for businesses seeking reliable protein ingredients.

About ETChem:

ETChem, a reputable Chinese Collagen factory manufacturer and supplier, is renowned for producing, stocking, exporting, and delivering the highest quality collagens. They include marine collagen, fish collagen, bovine collagen, chicken collagen, type I collagen, type II collagen and type III collagen etc. Their offerings, characterized by a neutral taste, instant solubility attributes, cater to a diverse range of industries. They serve nutraceutical, pharmaceutical, cosmeceutical, veterinary, as well as food and beverage finished product distributors, traders, and manufacturers across Europe, USA, Canada, Australia, Thailand, Japan, Korea, Brazil, and Chile, among others.

ETChem specialization includes exporting and delivering tailor-made collagen powder and finished collagen nutritional supplements. Their extensive product range covers sectors like Food and Beverage, Sports Nutrition, Weight Management, Dietary Supplements, Health and Wellness Products, ensuring comprehensive solutions to meet all your protein needs.

As a trusted company by leading global food and beverage brands and Fortune 500 companies, ETChem reinforces China’s reputation in the global arena. For more information or to sample their products, please contact them and email karen(at)et-chem.com today.