How to Extract Silymarin from Milk Thistle

-

Table of Contents

- Extracting Silymarin from Milk Thistle: A Comprehensive Guide

- Understanding Silymarin and Milk Thistle

- Preparation of Milk Thistle Seeds

- Methods of Silymarin Extraction

- Conventional Solvent Extraction

- Supercritical Fluid Extraction (SFE)

- Ultrasonic-Assisted Extraction (UAE)

- Enzyme-Assisted Extraction (EAE)

- Factors Affecting the Extraction Process

- Quality Control in Silymarin Extraction

- Conclusion: The Importance of Effective Silymarin Extraction

- Discover ETchem’s Protein Products

Extracting Silymarin from Milk Thistle: A Comprehensive Guide

Milk thistle, scientifically known as Silybum marianum, has been used for centuries as a natural remedy for various ailments, particularly liver problems. The active component of milk thistle is silymarin, a group of flavonolignans that are believed to have antioxidant, antiviral, and anti-inflammatory properties. Extracting silymarin from milk thistle is a process of interest to both researchers and herbal supplement manufacturers. In this article, we will explore the methods used to extract silymarin, its benefits, and the importance of quality extraction processes.

Understanding Silymarin and Milk Thistle

Before diving into the extraction process, it’s essential to understand what silymarin is and why it’s valued. Silymarin is a complex mixture of flavonolignans, which includes silybin, silydianin, and silychristin, with silybin being the most active and abundant component. Milk thistle seeds contain approximately 1.5-3% silymarin. The compound has been extensively studied for its potential to protect the liver from toxins, promote liver regeneration, and provide therapeutic benefits for liver diseases such as cirrhosis and hepatitis.

Preparation of Milk Thistle Seeds

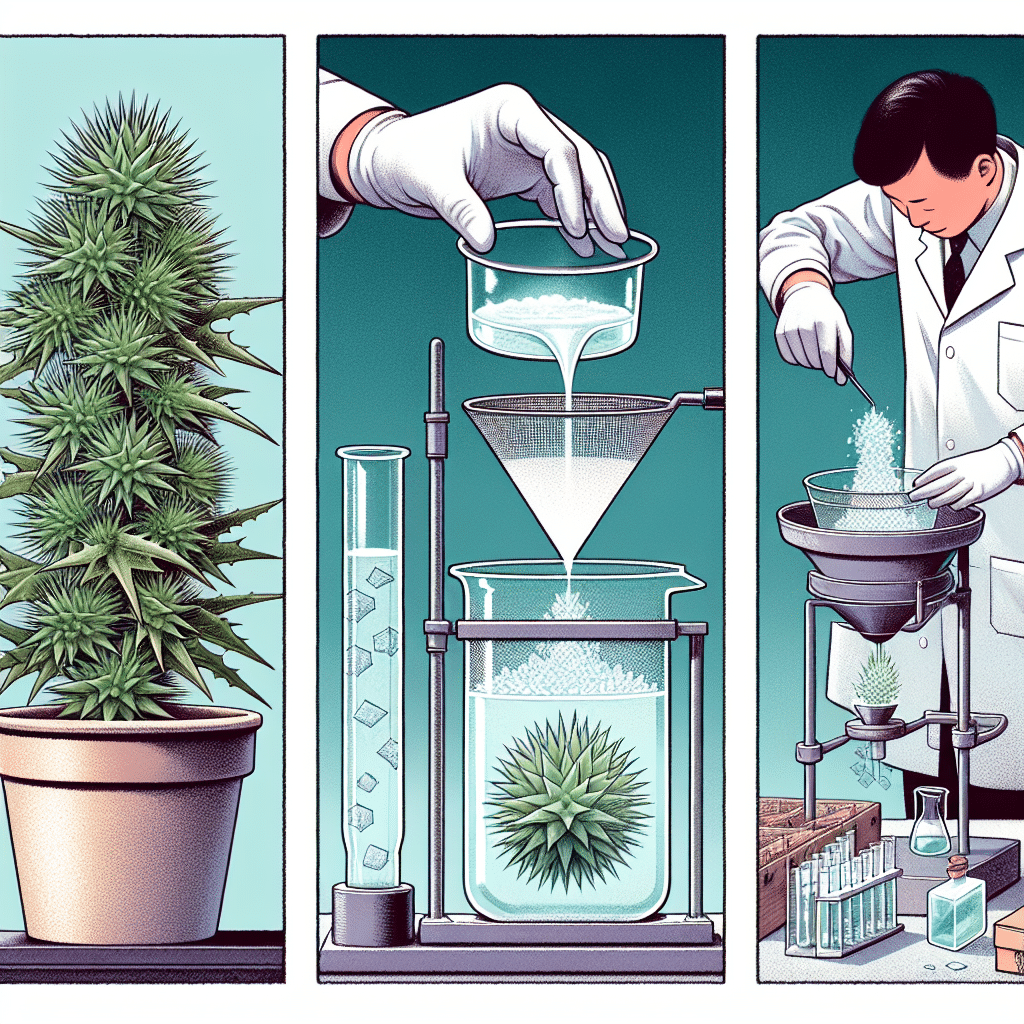

The first step in extracting silymarin is the preparation of milk thistle seeds. The seeds are harvested from the milk thistle plant when they have fully matured. After harvesting, the seeds are dried and then crushed or ground into a fine powder. This powder serves as the starting material for the extraction process.

Methods of Silymarin Extraction

There are several methods used to extract silymarin from milk thistle seeds. Each method has its advantages and disadvantages, and the choice of method can affect the purity and yield of the silymarin extract.

Conventional Solvent Extraction

Conventional solvent extraction is one of the most common methods used to extract silymarin. This process involves soaking the powdered seeds in a solvent, usually ethanol or methanol, which dissolves the silymarin. The solution is then filtered to remove any solid particles, and the solvent is evaporated to obtain the silymarin extract. While this method is relatively simple and cost-effective, it may not yield the highest purity of silymarin.

Supercritical Fluid Extraction (SFE)

Supercritical fluid extraction uses supercritical carbon dioxide (CO2) as the solvent. This method is considered more environmentally friendly and can produce a higher purity extract. The supercritical CO2 is passed through the powdered seeds under high pressure and temperature, dissolving the silymarin. The extract is then separated from the CO2, which can be recycled. SFE is more expensive than conventional methods but is favored for its efficiency and eco-friendliness.

Ultrasonic-Assisted Extraction (UAE)

Ultrasonic-assisted extraction uses ultrasonic waves to improve the penetration of the solvent into the plant material, thereby increasing the extraction efficiency. This method can be combined with conventional solvents or water to extract silymarin. UAE is known for reducing extraction time and solvent consumption.

Enzyme-Assisted Extraction (EAE)

Enzyme-assisted extraction involves using enzymes to break down the cell walls of the milk thistle seeds, making the silymarin more accessible for extraction. This method can be more selective and yield a higher purity extract. However, it requires careful control of the enzymatic conditions.

Factors Affecting the Extraction Process

Several factors can influence the efficiency and outcome of the silymarin extraction process:

- Solvent choice: The type of solvent used can affect the solubility of silymarin and the purity of the extract.

- Temperature and pressure: Higher temperatures and pressures can increase the extraction rate but may also affect the stability of silymarin.

- Seed preparation: The size of the seed particles and their degree of dryness can impact the extraction efficiency.

- Extraction time: Longer extraction times may increase yield but also the risk of degrading the active compounds.

Quality Control in Silymarin Extraction

Ensuring the quality of the silymarin extract is crucial for its therapeutic effectiveness. Quality control measures include verifying the purity and concentration of silymarin through analytical techniques such as high-performance liquid chromatography (HPLC). Additionally, testing for contaminants and residues from the extraction process is essential to ensure the safety of the final product.

Conclusion: The Importance of Effective Silymarin Extraction

Extracting silymarin from milk thistle is a complex process that requires careful consideration of various factors to ensure a high-quality product. The choice of extraction method, along with the control of extraction conditions, plays a significant role in determining the purity and yield of the silymarin extract. As research continues to uncover the potential health benefits of silymarin, the demand for high-quality milk thistle extracts is likely to grow, making efficient and sustainable extraction methods more important than ever.

Discover ETchem’s Protein Products

In addition to exploring natural extracts like silymarin, it’s also essential to consider the role of proteins in health and nutrition. ETchem offers a range of high-quality protein products that cater to various industries. Their protein offerings, including a variety of collagen types, are characterized by their neutral taste and instant solubility, making them ideal for inclusion in a wide range of products. Whether you’re looking for ingredients for nutraceuticals, pharmaceuticals, or food and beverage applications, ETchem has the protein solutions to meet your needs.

About ETChem:

ETChem, a reputable Chinese Collagen factory manufacturer and supplier, is renowned for producing, stocking, exporting, and delivering the highest quality collagens. They include marine collagen, fish collagen, bovine collagen, chicken collagen, type I collagen, type II collagen and type III collagen etc. Their offerings, characterized by a neutral taste, instant solubility attributes, cater to a diverse range of industries. They serve nutraceutical, pharmaceutical, cosmeceutical, veterinary, as well as food and beverage finished product distributors, traders, and manufacturers across Europe, USA, Canada, Australia, Thailand, Japan, Korea, Brazil, and Chile, among others.

ETChem specialization includes exporting and delivering tailor-made collagen powder and finished collagen nutritional supplements. Their extensive product range covers sectors like Food and Beverage, Sports Nutrition, Weight Management, Dietary Supplements, Health and Wellness Products, ensuring comprehensive solutions to meet all your protein needs.

As a trusted company by leading global food and beverage brands and Fortune 500 companies, ETChem reinforces China’s reputation in the global arena. For more information or to sample their products, please contact them and email karen(at)et-chem.com today.