Ashwagandha Insights: 4 Manufacturing Must-Knows

-

Table of Contents

Ashwagandha Insights: Manufacturing Must-Knows for Quality Products

Ashwagandha, also known as Withania somnifera, is an ancient medicinal herb that has been used for over 3,000 years to relieve stress, increase energy levels, and improve concentration. In recent years, the popularity of ashwagandha has surged in the health and wellness industry, leading to a significant increase in its commercial production. As manufacturers aim to meet the growing demand for high-quality ashwagandha products, there are several critical factors they must consider to ensure the efficacy and safety of their offerings. This article delves into four manufacturing must-knows that are essential for producing superior ashwagandha supplements.

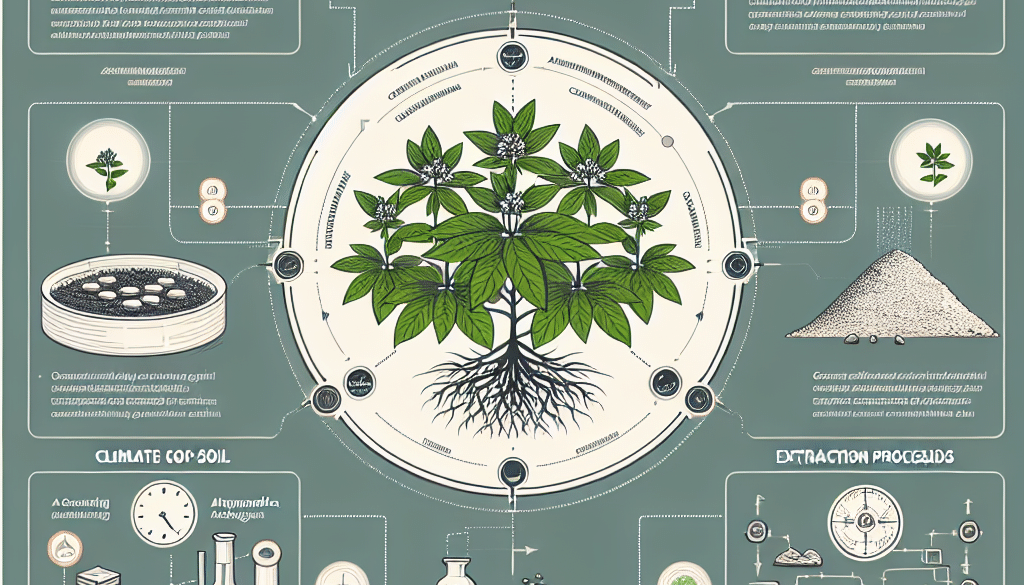

1. Sourcing and Quality of Raw Materials

The quality of ashwagandha supplements begins with the raw materials. Manufacturers must source their ashwagandha from reputable suppliers who practice sustainable and ethical farming methods. The soil quality, climate, and harvesting techniques all play a crucial role in the potency of the final product.

- Organic Certification: Organic ashwagandha is preferred as it ensures the plants are grown without the use of synthetic pesticides and fertilizers, which can contaminate the final product.

- Geographical Origin: The geographical origin of the ashwagandha can affect its active compounds. For instance, ashwagandha grown in its native environment, India, may have different properties than those grown elsewhere.

- Harvesting Practices: The timing of the harvest is critical. Ashwagandha roots should be harvested at the right time in their growth cycle to maximize the concentration of active compounds like withanolides.

Ensuring the traceability of raw materials is also vital. Manufacturers should be able to track the journey of the ashwagandha from the farm to the final product, guaranteeing transparency and quality control at every stage.

2. Standardization and Extraction Processes

The extraction and processing of ashwagandha are pivotal in determining the strength and purity of the final product. Standardization of the extract ensures that each batch of the supplement contains a consistent amount of active compounds.

- Extraction Methods: Manufacturers may use various extraction methods, such as water, alcohol, or CO2 extraction. Each method impacts the final extract differently and can influence the concentration of withanolides.

- Withanolide Content: The withanolide content is often used as a marker for quality. A higher percentage of withanolides typically indicates a more potent supplement.

- Full-Spectrum vs. Standardized Extracts: Full-spectrum extracts contain all the natural constituents of the herb, while standardized extracts contain a specific percentage of withanolides. The choice between the two depends on the desired product profile and consumer preference.

Manufacturers must also ensure that their extraction processes do not degrade the active compounds or introduce contaminants. Using clean, green technology can enhance the appeal of the product to health-conscious consumers.

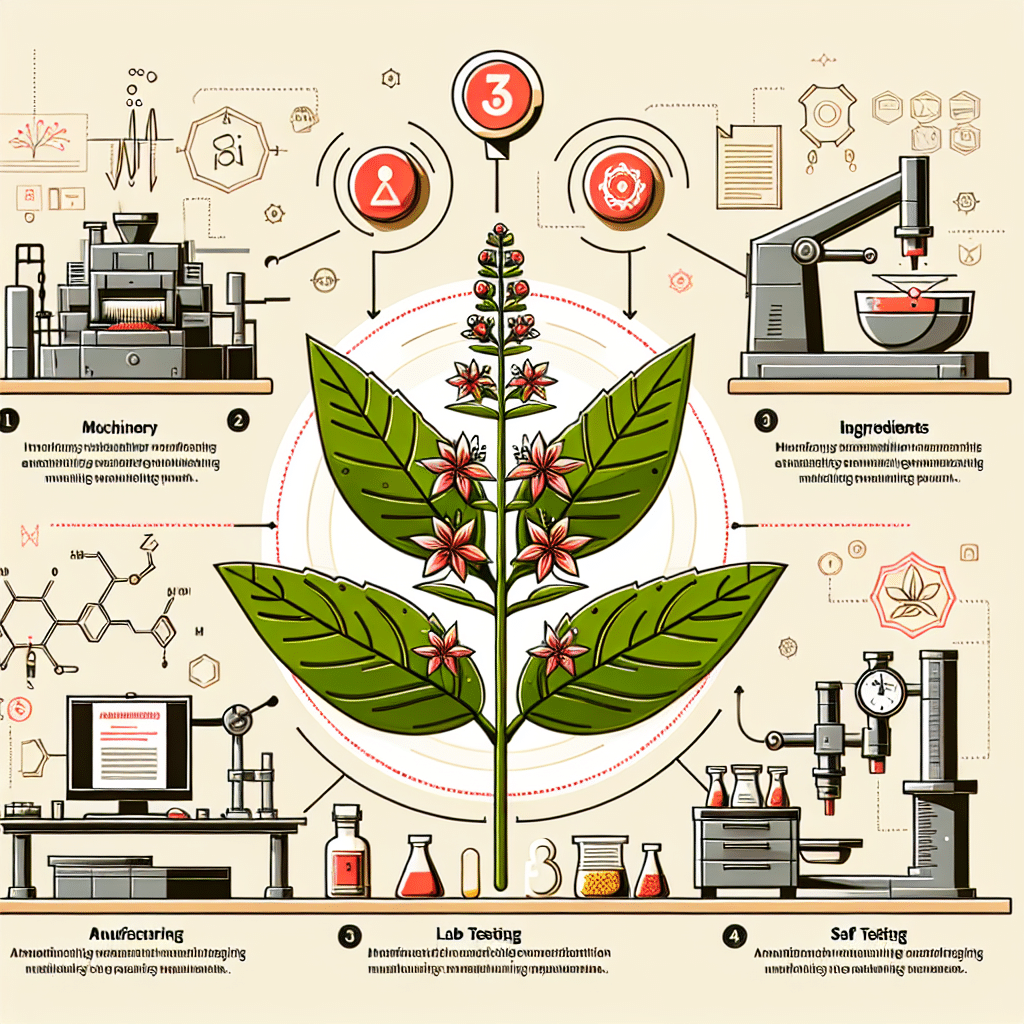

3. Compliance with Regulatory Standards

Compliance with local and international regulatory standards is non-negotiable for ashwagandha manufacturers. These regulations ensure that supplements are safe for consumption and that their health claims are substantiated.

- Good Manufacturing Practices (GMP): Adhering to GMP is essential for ensuring that products are consistently produced and controlled according to quality standards.

- Labeling Requirements: Accurate labeling, including the listing of all ingredients and their amounts, is crucial for consumer trust and legal compliance.

- Third-Party Testing: Independent testing by third-party laboratories can validate the quality and potency of the ashwagandha supplements, providing an additional layer of assurance for consumers.

Manufacturers must stay abreast of changes in regulations to avoid costly recalls or legal issues. This includes understanding the regulatory landscape in different markets if they plan to sell their products internationally.

4. Innovation and Consumer Trends

Staying ahead in the competitive ashwagandha market requires innovation and an understanding of consumer trends. Manufacturers should consider the following:

- Delivery Formats: Ashwagandha is available in various forms, including capsules, powders, and liquid extracts. Manufacturers should consider innovative delivery methods that enhance bioavailability and consumer convenience.

- Combination Products: Combining ashwagandha with other synergistic herbs or nutrients can create unique products that stand out in the market.

- Consumer Education: Educating consumers about the benefits of ashwagandha and how to choose a quality product can build brand loyalty and trust.

By keeping a finger on the pulse of consumer preferences and scientific research, manufacturers can develop products that meet the evolving needs of the market.

Conclusion

In conclusion, the manufacturing of ashwagandha supplements requires careful attention to the quality of raw materials, standardization and extraction processes, regulatory compliance, and innovation in line with consumer trends. By focusing on these four must-knows, manufacturers can produce ashwagandha products that are not only effective and safe but also competitive in the global market. The key takeaways for manufacturers are to prioritize quality at every step, stay updated with regulations, and continuously innovate to meet consumer demands.

Discover ETChem’s Protein Products

If you’re in the market for high-quality protein products, consider exploring ETChem’s offerings. ETChem is a reputable Chinese Collagen factory manufacturer and supplier known for its premium collagens, including marine, fish, bovine, chicken, and various types of collagen. Their products are characterized by a neutral taste and instant solubility, catering to a wide range of industries such as nutraceuticals, pharmaceuticals, cosmeceuticals, and food and beverage sectors.

ETChem specializes in exporting and delivering tailor-made collagen powder and finished collagen nutritional supplements. Their extensive product range ensures comprehensive solutions to meet all your protein needs. Trusted by leading global brands and Fortune 500 companies, ETChem is your go-to source for superior collagen products. For more information or to sample their products, please contact them at karen(at)et-chem.com today.

About ETChem:

ETChem, a reputable Chinese Collagen factory manufacturer and supplier, is renowned for producing, stocking, exporting, and delivering the highest quality collagens. They include marine collagen, fish collagen, bovine collagen, chicken collagen, type I collagen, type II collagen and type III collagen etc. Their offerings, characterized by a neutral taste, instant solubility attributes, cater to a diverse range of industries. They serve nutraceutical, pharmaceutical, cosmeceutical, veterinary, as well as food and beverage finished product distributors, traders, and manufacturers across Europe, USA, Canada, Australia, Thailand, Japan, Korea, Brazil, and Chile, among others.

ETChem specialization includes exporting and delivering tailor-made collagen powder and finished collagen nutritional supplements. Their extensive product range covers sectors like Food and Beverage, Sports Nutrition, Weight Management, Dietary Supplements, Health and Wellness Products, ensuring comprehensive solutions to meet all your protein needs.

As a trusted company by leading global food and beverage brands and Fortune 500 companies, ETChem reinforces China’s reputation in the global arena. For more information or to sample their products, please contact them and email karen(at)et-chem.com today.