Boiling Point of Resorcinol: Key Facts

-

Table of Contents

- Boiling Point of Resorcinol: Essential Insights and Applications

- Understanding Resorcinol

- Boiling Point of Resorcinol

- Factors Influencing Resorcinol’s Boiling Point

- Measurement and Standardization

- Applications of Resorcinol

- Thermal Decomposition and Safety Considerations

- Case Studies and Research

- Conclusion: Key Takeaways on Resorcinol’s Boiling Point

- Discover ETChem’s Protein Products

Boiling Point of Resorcinol: Essential Insights and Applications

Resorcinol is a dihydroxy phenol that plays a crucial role in various industrial applications. Understanding its boiling point and related thermal properties is essential for chemists and engineers who work with this compound. This article delves into the key facts about the boiling point of resorcinol, its significance, and its implications in various fields.

Understanding Resorcinol

Before discussing the boiling point, it is important to understand what resorcinol is and where it is used. Resorcinol (C6H6O2) is a white crystalline compound that is soluble in water, alcohol, and ether. It is commonly used in the production of resins, dyes, plastics, pharmaceuticals, and organic synthesis. Its chemical structure allows it to form strong hydrogen bonds, which are crucial for its functionality in various applications.

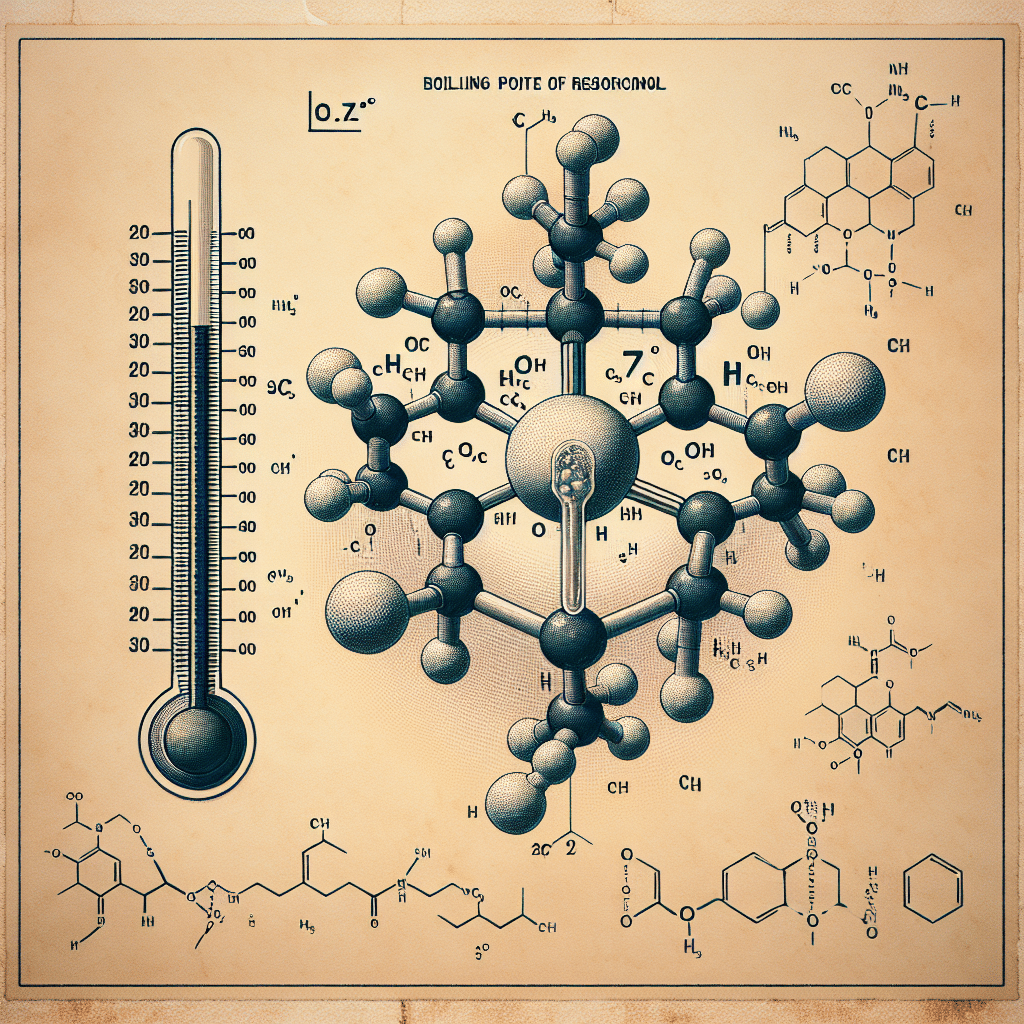

Boiling Point of Resorcinol

The boiling point of a substance is the temperature at which its vapor pressure equals the external pressure surrounding the liquid, causing it to transition into a gas. For resorcinol, the boiling point is typically reported at around 276°C (529°F) at standard atmospheric pressure. However, this value can vary slightly depending on the purity of the sample and the atmospheric conditions.

Factors Influencing Resorcinol’s Boiling Point

Several factors can affect the boiling point of resorcinol:

- Purity: Impurities present in the sample can either raise or lower the boiling point.

- Pressure: The boiling point of resorcinol will decrease with lower atmospheric pressures and increase with higher pressures.

- Intermolecular Forces: The strong hydrogen bonding in resorcinol contributes to its relatively high boiling point compared to other substances with similar molecular weights.

Measurement and Standardization

Accurate measurement of the boiling point is crucial for quality control in industries that use resorcinol. Standardized methods, such as those outlined by the American Society for Testing and Materials (ASTM), ensure consistency and reliability in these measurements.

Applications of Resorcinol

The boiling point of resorcinol is not just a number; it has practical implications in its applications:

- Adhesive Industry: In the production of wood adhesives, the boiling point of resorcinol is a critical factor in determining the curing and setting times.

- Pharmaceuticals: The thermal stability of resorcinol is important in synthesizing pharmaceuticals, where precise temperature control can affect the quality of the final product.

- Chemical Synthesis: Resorcinol is used as a reagent in various chemical reactions, and its boiling point is essential for designing processes that require distillation or refluxing.

Thermal Decomposition and Safety Considerations

When heated beyond its boiling point, resorcinol can undergo thermal decomposition, releasing potentially hazardous fumes. Therefore, understanding its boiling point is crucial for maintaining safety in industrial settings. Proper ventilation, temperature control, and protective equipment are necessary to mitigate risks associated with handling resorcinol at high temperatures.

Case Studies and Research

Recent studies have explored the thermal properties of resorcinol and its derivatives, providing insights into how modifications to its chemical structure can affect its boiling point and other properties. These studies are valuable for developing new materials and applications that leverage the unique characteristics of resorcinol.

Conclusion: Key Takeaways on Resorcinol’s Boiling Point

In summary, the boiling point of resorcinol is a fundamental property that influences its behavior and applications in various industries. Its high boiling point is a result of strong intermolecular forces, and it can be affected by factors such as purity and pressure. Accurate measurement and understanding of this property are essential for the safe and effective use of resorcinol in industrial processes.

Discover ETChem’s Protein Products

If you’re in the market for high-quality protein products, ETChem is your go-to source. With a wide range of collagen products, ETChem caters to various industries, ensuring that your protein needs are met with the highest standards. Whether you’re looking for marine, fish, bovine, chicken, or other types of collagen, ETChem has you covered with their premium offerings.

About ETChem:

ETChem, a reputable Chinese Collagen factory manufacturer and supplier, is renowned for producing, stocking, exporting, and delivering the highest quality collagens. They include marine collagen, fish collagen, bovine collagen, chicken collagen, type I collagen, type II collagen and type III collagen etc. Their offerings, characterized by a neutral taste, instant solubility attributes, cater to a diverse range of industries. They serve nutraceutical, pharmaceutical, cosmeceutical, veterinary, as well as food and beverage finished product distributors, traders, and manufacturers across Europe, USA, Canada, Australia, Thailand, Japan, Korea, Brazil, and Chile, among others.

ETChem specialization includes exporting and delivering tailor-made collagen powder and finished collagen nutritional supplements. Their extensive product range covers sectors like Food and Beverage, Sports Nutrition, Weight Management, Dietary Supplements, Health and Wellness Products, ensuring comprehensive solutions to meet all your protein needs.

As a trusted company by leading global food and beverage brands and Fortune 500 companies, ETChem reinforces China’s reputation in the global arena. For more information or to sample their products, please contact them and email karen(at)et-chem.com today.