Sustainability Goals: Beyond the Paper Straw in Manufacturing

-

Table of Contents

- Sustainability Goals in Manufacturing: Beyond the Paper Straw

- Understanding the Scope of Sustainable Manufacturing

- Resource Efficiency and Waste Reduction

- Renewable Energy Adoption in Manufacturing

- Supply Chain Sustainability

- Product Design Innovation

- Measuring Success: Metrics and Certifications

- Challenges and Opportunities

- Conclusion: The Road Ahead for Sustainable Manufacturing

- ETchem: Leading the Way in Sustainable Protein Products

Sustainability Goals in Manufacturing: Beyond the Paper Straw

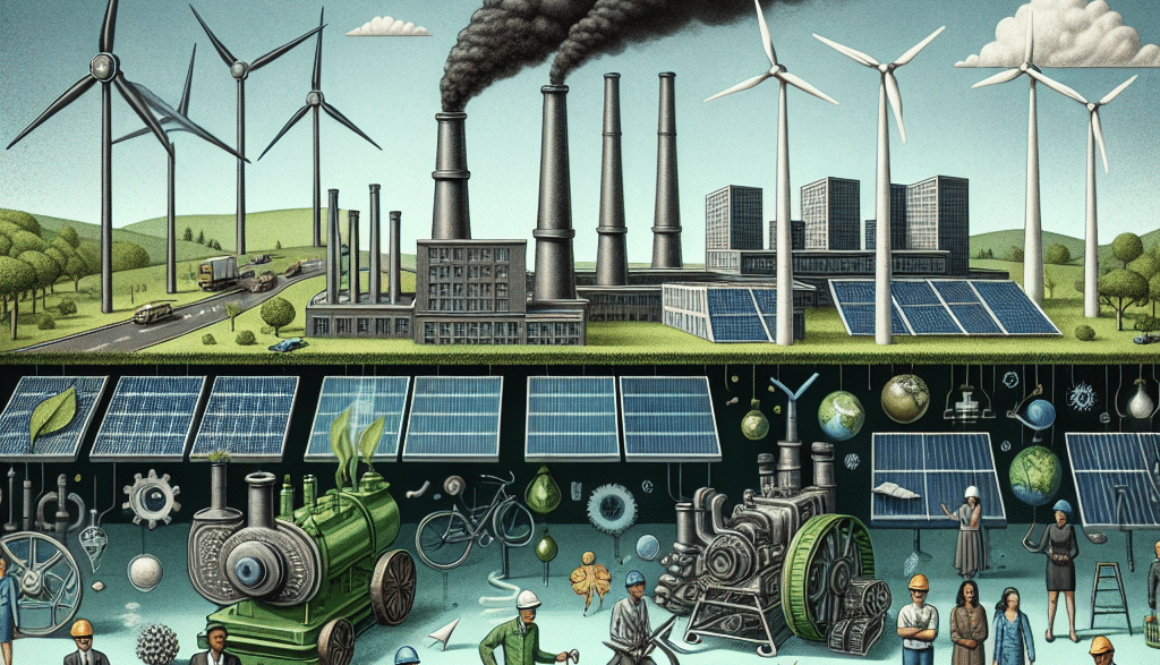

When it comes to sustainability in manufacturing, the conversation often starts and stops at the consumer level, with initiatives like paper straws becoming the poster child for environmental efforts. However, true sustainability requires a much deeper integration of eco-friendly practices throughout the manufacturing process. This article delves into the broader spectrum of sustainability goals that extend far beyond the paper straw, exploring innovative strategies and solutions that manufacturers are implementing to reduce their environmental footprint.

Understanding the Scope of Sustainable Manufacturing

Sustainable manufacturing is a comprehensive approach that considers the entire lifecycle of a product, from raw material extraction to end-of-life disposal. The goal is to minimize environmental impact while maintaining economic viability and ensuring social responsibility. This involves a range of practices, including:

- Resource efficiency

- Waste reduction

- Renewable energy adoption

- Supply chain sustainability

- Product design innovation

Resource Efficiency and Waste Reduction

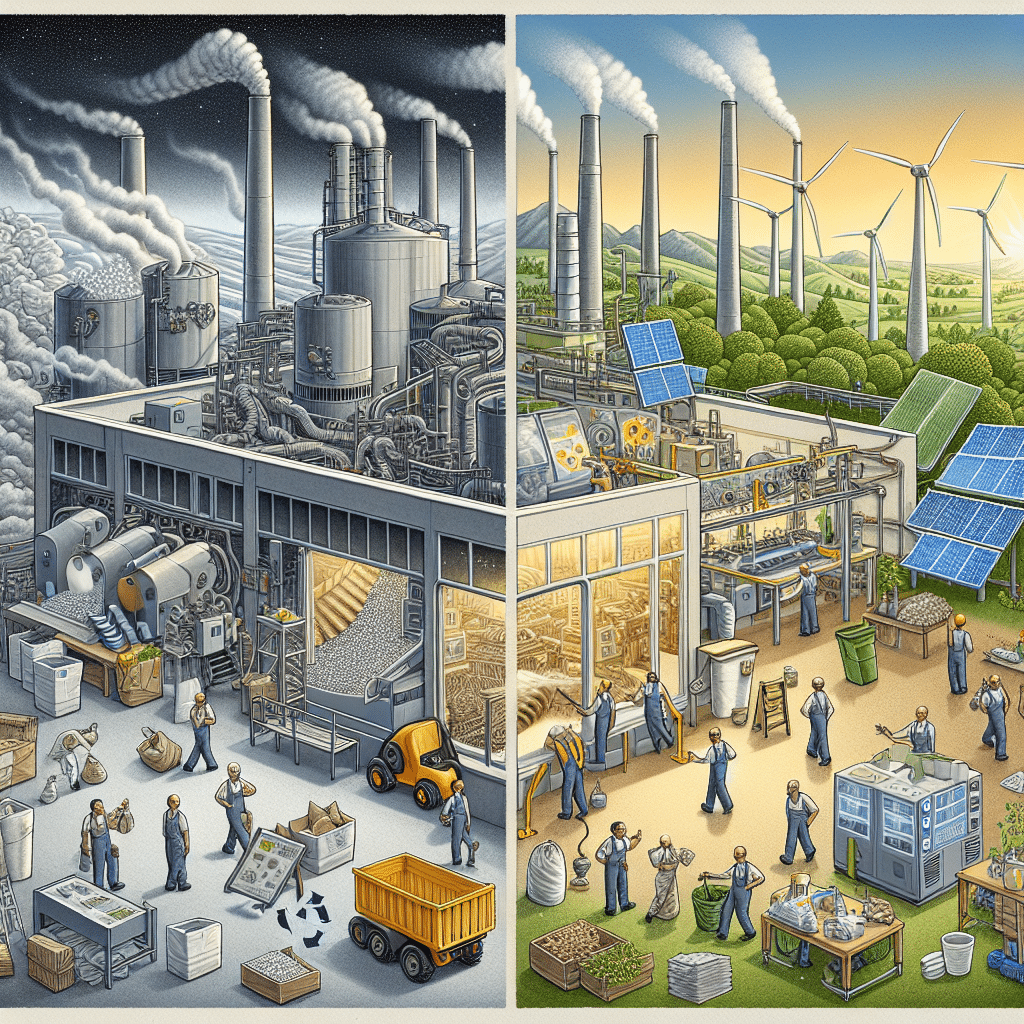

One of the primary objectives in sustainable manufacturing is to use resources more efficiently and reduce waste. This can be achieved through various means, such as:

- Implementing lean manufacturing techniques to minimize excess material use

- Adopting closed-loop systems that recycle water and materials within the production process

- Utilizing advanced technologies for precision manufacturing to reduce scrap rates

Case studies from companies like Toyota and General Electric showcase the success of these strategies, with Toyota’s famous Just-in-Time system significantly reducing inventory waste, and GE’s “Ecomagination” initiative driving resource efficiency across its product lines.

Renewable Energy Adoption in Manufacturing

Transitioning to renewable energy sources is another critical aspect of sustainable manufacturing. Manufacturers are increasingly investing in solar, wind, and other renewable energy systems to power their operations. For example, Apple has committed to powering all its facilities with 100% renewable energy, a goal it has already achieved in its retail stores, offices, and data centers worldwide.

Supply Chain Sustainability

A manufacturer’s environmental impact extends beyond its own operations to the entire supply chain. Sustainable supply chain management involves:

- Working with suppliers who adhere to environmental standards

- Optimizing logistics to reduce carbon emissions

- Implementing sustainable packaging solutions

Companies like Unilever and Walmart have set ambitious targets for their suppliers, pushing for greater transparency and sustainability throughout their supply chains.

Product Design Innovation

Innovative product design plays a pivotal role in sustainability. Designing products for longevity, repairability, and recyclability can significantly reduce their environmental impact. For instance, Fairphone has gained attention for creating a modular smartphone designed to be easily repaired and upgraded, challenging the throwaway culture prevalent in the tech industry.

Measuring Success: Metrics and Certifications

To gauge the effectiveness of sustainability initiatives, manufacturers rely on various metrics and certifications, such as:

- Carbon footprint analysis

- Life cycle assessments

- ISO 14001 environmental management standards

- Energy Star and LEED certifications for energy-efficient buildings

These tools help manufacturers track progress, identify areas for improvement, and communicate their commitment to sustainability to stakeholders.

Challenges and Opportunities

Despite the clear benefits, sustainable manufacturing also presents challenges. These include the upfront costs of green technologies, the complexity of overhauling supply chains, and the need for skilled workers to implement and maintain sustainable practices. However, the opportunities for innovation, cost savings, and brand enhancement are driving more manufacturers to embrace sustainability as a core business strategy.

Conclusion: The Road Ahead for Sustainable Manufacturing

The journey towards sustainable manufacturing is ongoing and multifaceted. Beyond the symbolic paper straw, manufacturers must adopt a holistic approach that encompasses every aspect of their operations. By doing so, they can not only reduce their environmental impact but also position themselves as leaders in a future where sustainability is not just a trend but a business imperative.

ETchem: Leading the Way in Sustainable Protein Products

As manufacturers strive for sustainability, the demand for eco-friendly raw materials is on the rise. ETchem is at the forefront of this movement, offering a range of sustainable protein products that cater to various industries. Their commitment to quality and sustainability makes them an ideal partner for businesses looking to enhance their green credentials.

About ETChem:

ETChem, a reputable Chinese Collagen factory manufacturer and supplier, is renowned for producing, stocking, exporting, and delivering the highest quality collagens. They include marine collagen, fish collagen, bovine collagen, chicken collagen, type I collagen, type II collagen and type III collagen etc. Their offerings, characterized by a neutral taste, instant solubility attributes, cater to a diverse range of industries. They serve nutraceutical, pharmaceutical, cosmeceutical, veterinary, as well as food and beverage finished product distributors, traders, and manufacturers across Europe, USA, Canada, Australia, Thailand, Japan, Korea, Brazil, and Chile, among others.

ETChem specialization includes exporting and delivering tailor-made collagen powder and finished collagen nutritional supplements. Their extensive product range covers sectors like Food and Beverage, Sports Nutrition, Weight Management, Dietary Supplements, Health and Wellness Products, ensuring comprehensive solutions to meet all your protein needs.

As a trusted company by leading global food and beverage brands and Fortune 500 companies, ETChem reinforces China’s reputation in the global arena. For more information or to sample their products, please contact them and email karen(at)et-chem.com today.