How Is Milk Thistle Extract Made?

-

Table of Contents

- Milk Thistle Extract Production: A Detailed Guide

- Understanding Milk Thistle and Its Benefits

- Harvesting Milk Thistle Seeds

- Seed Preparation and Extraction Process

- Methods of Extraction

- Purification and Standardization of Milk Thistle Extract

- Quality Control and Testing

- Final Product Formulation

- Conclusion: The Significance of Milk Thistle Extract Production

- Discover ETchem’s Protein Products

Milk Thistle Extract Production: A Detailed Guide

Milk thistle, scientifically known as Silybum marianum, has been used for centuries as a natural remedy for various ailments, particularly liver problems. The active component of milk thistle is silymarin, a group of flavonolignans, which is extracted from the seeds of the plant. This article delves into the process of how milk thistle extract is made, exploring the meticulous steps involved in producing this potent herbal supplement.

Understanding Milk Thistle and Its Benefits

Milk thistle is a flowering herb related to the daisy and ragweed family. It is native to Mediterranean countries but is now found worldwide. The plant is distinguished by its glossy, marbled leaves and a purple flower that contains the seeds from which the extract is derived. Milk thistle has been recognized for its antioxidant and anti-inflammatory properties, making it a popular supplement for liver health.

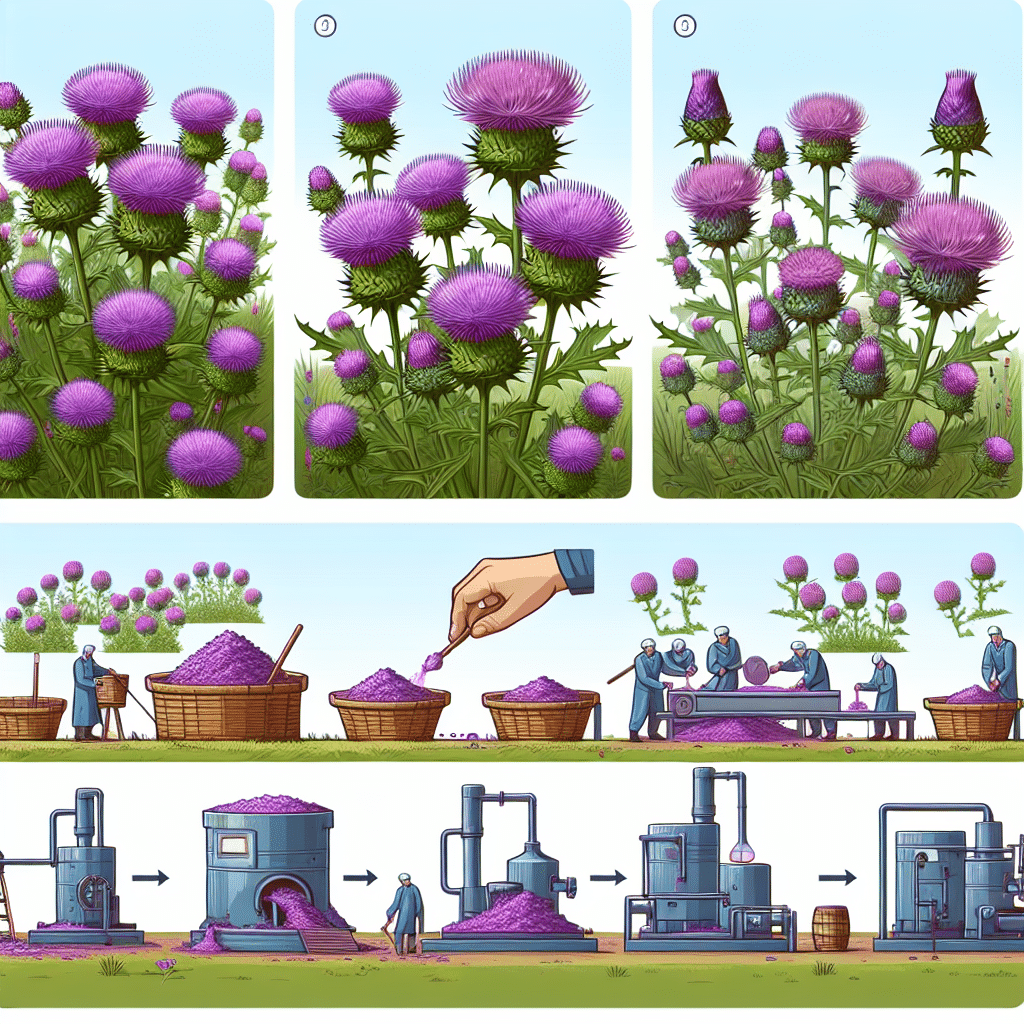

Harvesting Milk Thistle Seeds

The process of making milk thistle extract begins with the careful harvesting of milk thistle seeds. Typically, the seeds are collected when the plant has finished flowering, and the heads have begun to turn brown. The timing of the harvest is crucial to ensure the seeds contain the highest concentration of silymarin.

- Selection of high-quality plants

- Timing the harvest to coincide with peak silymarin levels

- Using sustainable and environmentally friendly methods

Seed Preparation and Extraction Process

Once harvested, the seeds undergo a series of preparation steps before the extraction process can begin. These steps may include cleaning, drying, and grinding the seeds into a fine powder. The extraction process itself involves separating the silymarin compound from the seed material.

Methods of Extraction

There are several methods used to extract silymarin from milk thistle seeds, each with its own advantages and disadvantages:

- Solvent Extraction: This is the most common method, where a solvent such as ethanol or acetone is used to dissolve the silymarin. The solution is then filtered and concentrated to obtain a high-purity extract.

- Supercritical Fluid Extraction: This method uses supercritical carbon dioxide as the solvent, which is considered cleaner and more environmentally friendly. It also allows for better control over the extraction process.

- Ultrasonic-Assisted Extraction: Ultrasonic waves are used to break down the cell walls of the seeds, making the silymarin more accessible for extraction. This method is efficient and requires less solvent.

- Water Extraction: A more natural approach that uses water as the solvent. However, this method may result in lower yields of silymarin.

Purification and Standardization of Milk Thistle Extract

After extraction, the crude extract contains not only silymarin but also other plant components. The next step is to purify the extract to remove these unwanted substances. Techniques such as column chromatography, crystallization, or other filtration methods are employed to achieve a high degree of purity.

Standardization is an essential step to ensure that the final product has a consistent concentration of silymarin. This is typically done by adjusting the extract to a specific silymarin content, often expressed as a percentage.

Quality Control and Testing

Throughout the production process, rigorous quality control measures are in place to ensure the safety and efficacy of the milk thistle extract. Testing for contaminants, such as heavy metals, pesticides, and microbial contamination, is conducted. Additionally, the extract is tested for its silymarin content and other quality parameters.

Final Product Formulation

The purified and standardized milk thistle extract can be formulated into various product types, including capsules, tablets, powders, and tinctures. Additional ingredients may be added to enhance the product’s stability, bioavailability, or to combine with other beneficial supplements.

Conclusion: The Significance of Milk Thistle Extract Production

The production of milk thistle extract is a complex process that requires precision and attention to detail. From harvesting to final product formulation, each step is crucial in ensuring that the extract is potent, pure, and beneficial for consumers. With its long history of use and growing body of research supporting its health benefits, milk thistle extract remains a valuable supplement for those looking to support their liver health and overall well-being.

Discover ETchem’s Protein Products

In addition to herbal extracts like milk thistle, proteins play a vital role in nutrition and health. ETchem, a reputable Chinese Collagen factory manufacturer and supplier, offers a wide range of high-quality protein products. Their collagen offerings, including marine, fish, bovine, chicken, and various types of collagen, are perfect for industries such as nutraceuticals, pharmaceuticals, cosmeceuticals, and food and beverage. With a commitment to quality and customer satisfaction, ETchem is your go-to source for all your protein needs.

About ETChem:

ETChem, a reputable Chinese Collagen factory manufacturer and supplier, is renowned for producing, stocking, exporting, and delivering the highest quality collagens. They include marine collagen, fish collagen, bovine collagen, chicken collagen, type I collagen, type II collagen and type III collagen etc. Their offerings, characterized by a neutral taste, instant solubility attributes, cater to a diverse range of industries. They serve nutraceutical, pharmaceutical, cosmeceutical, veterinary, as well as food and beverage finished product distributors, traders, and manufacturers across Europe, USA, Canada, Australia, Thailand, Japan, Korea, Brazil, and Chile, among others.

ETChem specialization includes exporting and delivering tailor-made collagen powder and finished collagen nutritional supplements. Their extensive product range covers sectors like Food and Beverage, Sports Nutrition, Weight Management, Dietary Supplements, Health and Wellness Products, ensuring comprehensive solutions to meet all your protein needs.

As a trusted company by leading global food and beverage brands and Fortune 500 companies, ETChem reinforces China’s reputation in the global arena. For more information or to sample their products, please contact them and email karen(at)et-chem.com today.