Melting Point of Resorcinol: Key Facts

-

Table of Contents

- Melting Point of Resorcinol: Essential Insights and Applications

- Understanding Resorcinol

- The Melting Point of Resorcinol

- Factors Influencing Resorcinol’s Melting Point

- Significance of the Melting Point in Industrial Applications

- Measuring the Melting Point of Resorcinol

- Resorcinol in Research and Development

- Case Studies and Statistics

- Conclusion: The Importance of Resorcinol’s Melting Point

- Discover ETChem’s Protein Products

Melting Point of Resorcinol: Essential Insights and Applications

Resorcinol is a dihydroxy benzene derivative that plays a crucial role in various industrial applications. Understanding its melting point is vital for chemists and engineers who work with this compound in different contexts. This article delves into the key facts about the melting point of resorcinol, its significance, and its implications in various industries.

Understanding Resorcinol

Before we explore the melting point of resorcinol, it’s important to understand what resorcinol is and where it’s used. Resorcinol is a white, crystalline solid that belongs to the family of phenolic compounds. It is known for its antiseptic and disinfectant properties and is commonly used in:

- Pharmaceuticals for topical skin treatments

- Production of resins and adhesives

- Manufacturing dyes and plastics

- Chemical intermediates in the synthesis of organic compounds

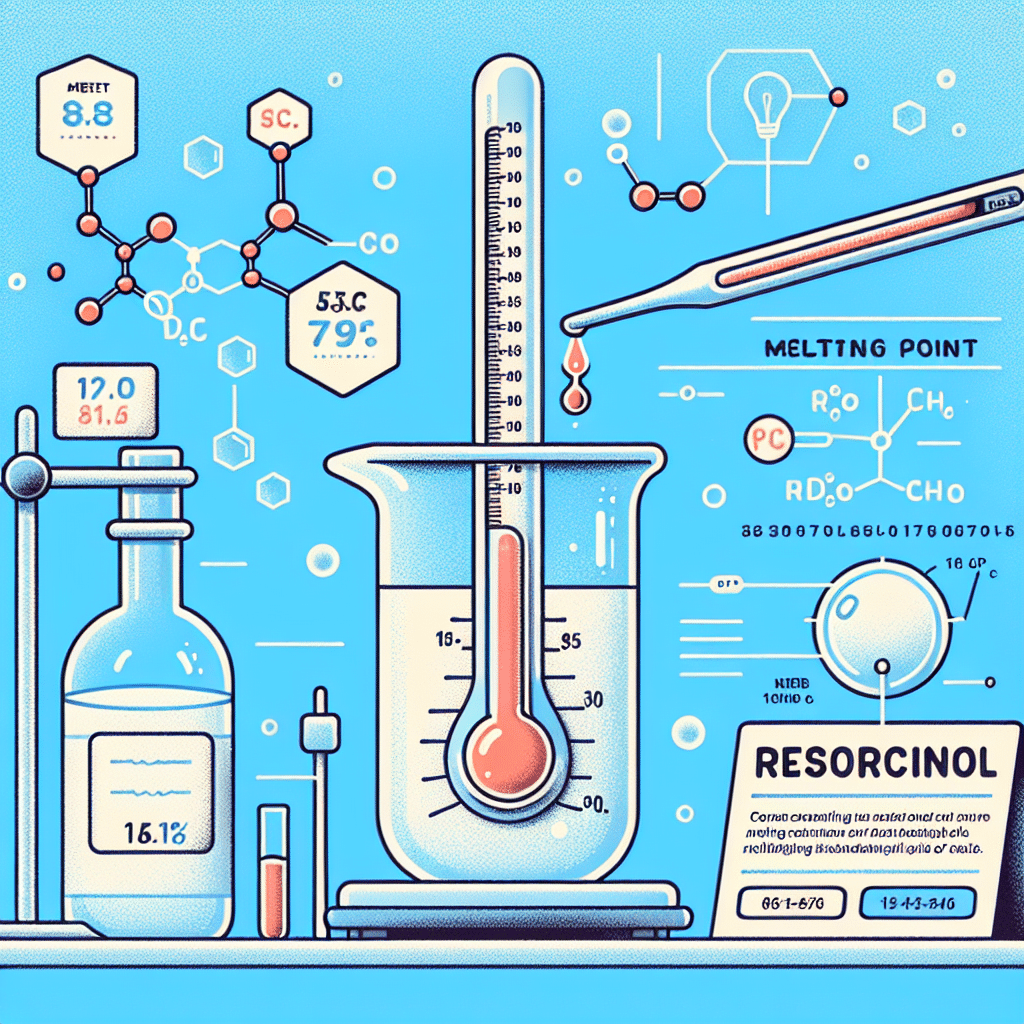

The Melting Point of Resorcinol

The melting point of a substance is a fundamental physical property that indicates the temperature at which it transitions from a solid to a liquid state. For resorcinol, this melting point is typically reported to be around 110°C (230°F). However, it’s important to note that the purity of the resorcinol and the presence of impurities can affect this value.

Factors Influencing Resorcinol’s Melting Point

Several factors can influence the melting point of resorcinol:

- Purity: The presence of impurities can lower the melting point due to the disruption of the crystal lattice structure.

- Pressure: Changes in atmospheric pressure can slightly alter the melting point.

- Crystal Form: Different polymorphs of resorcinol may have varying melting points.

Significance of the Melting Point in Industrial Applications

The melting point of resorcinol is a critical parameter in its industrial applications. For instance:

- In adhesive production, the melting point determines the processing temperatures and the final properties of the adhesive.

- In pharmaceuticals, the melting point ensures the stability and efficacy of resorcinol-based medications.

- In the synthesis of other chemicals, the melting point helps in designing the appropriate reaction conditions.

Measuring the Melting Point of Resorcinol

Accurate determination of the melting point is essential for quality control and research purposes. Techniques such as capillary melting point apparatus and differential scanning calorimetry (DSC) are commonly used to measure the melting point of resorcinol.

Resorcinol in Research and Development

Research into resorcinol and its derivatives continues to expand its applications. Studies on resorcinol’s melting point have led to the development of new materials and improved industrial processes. For example, resorcinol-formaldehyde resins benefit from precise melting point control to achieve desired performance characteristics.

Case Studies and Statistics

Case studies in the adhesive industry show that controlling the melting point of resorcinol can lead to stronger and more durable bonds, especially in wood products and automotive applications. Statistics from the pharmaceutical industry indicate that resorcinol-based treatments are more effective when the compound’s melting point is taken into consideration during formulation.

Conclusion: The Importance of Resorcinol’s Melting Point

In summary, the melting point of resorcinol is a key property that influences its behavior and utility in various industries. Accurate knowledge and control of this parameter ensure the quality and performance of resorcinol-containing products. As research progresses, the importance of understanding the melting point of resorcinol will continue to grow, driving innovation and efficiency in its applications.

Discover ETChem’s Protein Products

If you’re in the market for high-quality protein products, ETChem is your go-to source. With a wide range of collagen products, ETChem caters to various industries, ensuring that your protein needs are met with the highest standards. Whether you’re looking for marine, bovine, or chicken collagen, ETChem has the right solution for you.

About ETChem:

ETChem, a reputable Chinese Collagen factory manufacturer and supplier, is renowned for producing, stocking, exporting, and delivering the highest quality collagens. They include marine collagen, fish collagen, bovine collagen, chicken collagen, type I collagen, type II collagen and type III collagen etc. Their offerings, characterized by a neutral taste, instant solubility attributes, cater to a diverse range of industries. They serve nutraceutical, pharmaceutical, cosmeceutical, veterinary, as well as food and beverage finished product distributors, traders, and manufacturers across Europe, USA, Canada, Australia, Thailand, Japan, Korea, Brazil, and Chile, among others.

ETChem specialization includes exporting and delivering tailor-made collagen powder and finished collagen nutritional supplements. Their extensive product range covers sectors like Food and Beverage, Sports Nutrition, Weight Management, Dietary Supplements, Health and Wellness Products, ensuring comprehensive solutions to meet all your protein needs.

As a trusted company by leading global food and beverage brands and Fortune 500 companies, ETChem reinforces China’s reputation in the global arena. For more information or to sample their products, please contact them and email karen(at)et-chem.com today.