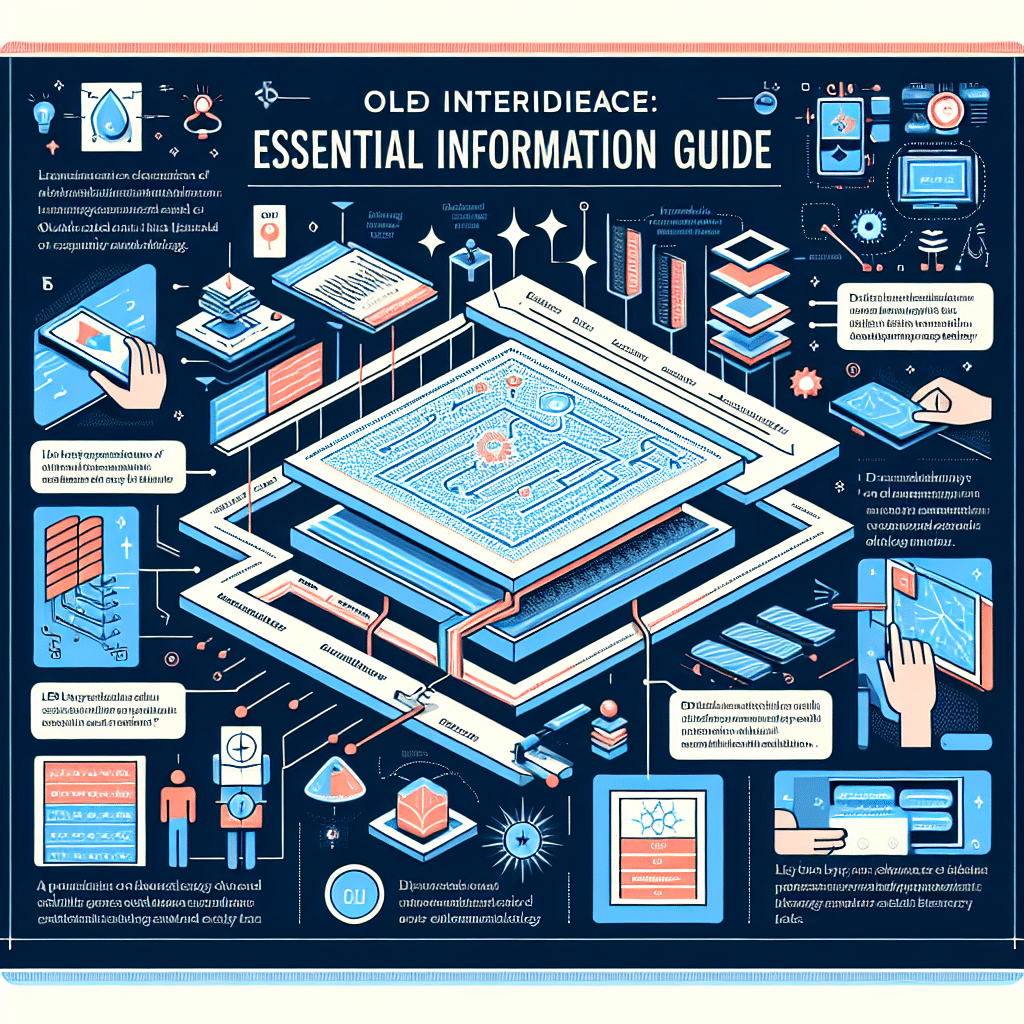

OLED Intermediate: Essential Information Guide

-

Table of Contents

- OLED Intermediates: Your Essential Information Guide

- Understanding OLED Technology

- The Role of OLED Intermediates

- Types of OLED Intermediates

- Manufacturing Process of OLED Displays

- Advantages of OLED Displays

- Challenges and Solutions in OLED Intermediate Production

- Case Studies and Applications

- Future Trends in OLED Technology

- Conclusion

- Discover ETChem’s Protein Products

OLED Intermediates: Your Essential Information Guide

OLED technology has revolutionized the way we experience visual media, offering unparalleled color accuracy, contrast ratios, and energy efficiency. At the heart of this technology are OLED intermediates, the chemical compounds that form the building blocks of OLED displays. This guide delves into the essential information about OLED intermediates, their role in display technology, and the future of OLED applications.

Understanding OLED Technology

Organic Light Emitting Diodes (OLEDs) are a type of light-emitting technology used in screens and displays. Unlike traditional LED or LCD displays that require a backlight, OLEDs emit their own light when an electric current passes through them. This self-emissive property allows for thinner displays, deeper blacks, and a wider viewing angle.

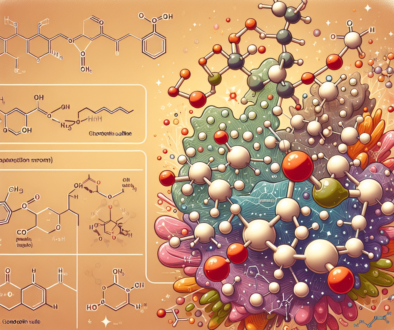

The Role of OLED Intermediates

OLED intermediates are crucial in the manufacturing of OLED panels. These organic compounds are used to create the emissive and conductive layers within an OLED display. The quality and composition of these intermediates directly affect the performance, color purity, and lifespan of the final OLED product.

Types of OLED Intermediates

There are several types of OLED intermediates, each serving a specific function within the OLED structure:

- Host Materials: These compounds form the main component of the emissive layer, hosting the dopant materials that emit light.

- Dopant Materials: These are added to the host materials to fine-tune the color emission and improve efficiency.

- Hole Transport Materials (HTMs): HTMs facilitate the movement of positive charges within the OLED, improving the injection and transport of holes from the anode.

- Electron Transport Materials (ETMs): ETMs are used to transport electrons from the cathode, complementing the HTMs.

- Hole Blocking Materials (HBMs): These materials prevent holes from moving to the wrong layer, ensuring efficient electron-hole recombination.

- Encapsulation Materials: These protect the sensitive organic layers from environmental factors like moisture and oxygen.

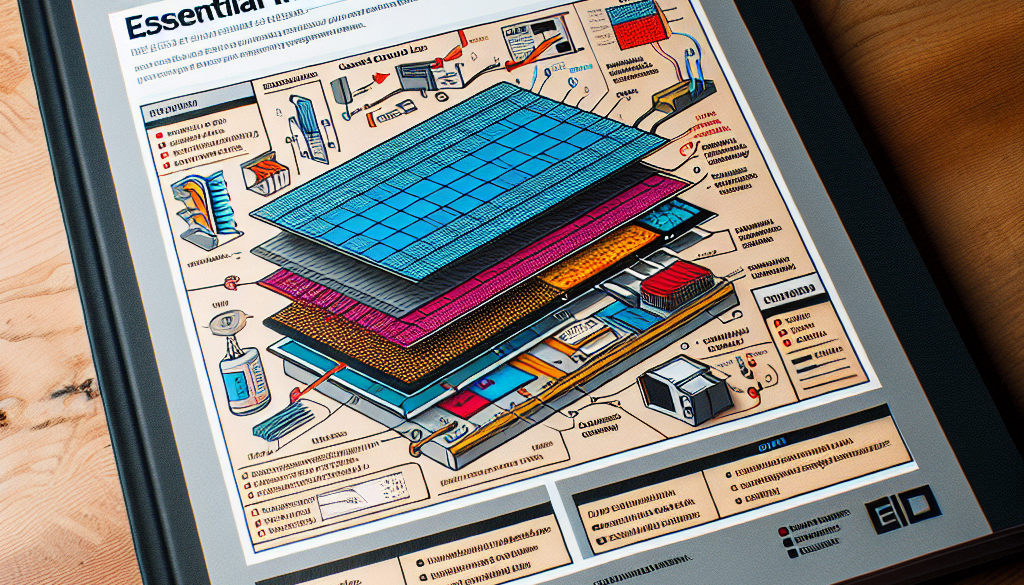

Manufacturing Process of OLED Displays

The manufacturing process of OLED displays involves several steps, including the deposition of OLED intermediates onto a substrate. This can be done through various techniques such as vacuum thermal evaporation or inkjet printing. The precision and purity of the intermediates are critical to achieving high-quality displays.

Advantages of OLED Displays

OLED displays offer numerous advantages over traditional display technologies:

- Superior image quality with high contrast ratios and true blacks.

- Lower power consumption due to the absence of a backlight.

- Flexibility in design, enabling curved and foldable displays.

- Faster response times suitable for high-definition video and gaming.

Challenges and Solutions in OLED Intermediate Production

Despite the advantages, there are challenges in OLED intermediate production, such as the synthesis of complex organic compounds and ensuring their purity. Advanced chemical processing and purification techniques are employed to overcome these challenges, ensuring the intermediates meet stringent industry standards.

Case Studies and Applications

OLED technology is not limited to consumer electronics. It has found applications in various sectors:

- Smartphones and tablets with vibrant, energy-efficient displays.

- High-end televisions offering cinematic viewing experiences.

- Automotive displays for dashboards and infotainment systems.

- Wearable technology with flexible screens.

- Lighting solutions with organic light panels.

Case studies from leading manufacturers demonstrate the potential of OLED technology in creating innovative products that push the boundaries of design and functionality.

Future Trends in OLED Technology

The future of OLED technology is bright, with ongoing research and development focusing on improving efficiency, lifespan, and production costs. Innovations such as transparent OLEDs and rollable screens are on the horizon, promising to transform the way we interact with technology.

Conclusion

OLED intermediates are the unsung heroes behind the captivating displays we use every day. Understanding their role and the intricacies of OLED technology is essential for appreciating the advancements in modern display technology. With continuous improvements and innovative applications, OLEDs are set to remain at the forefront of the display industry.

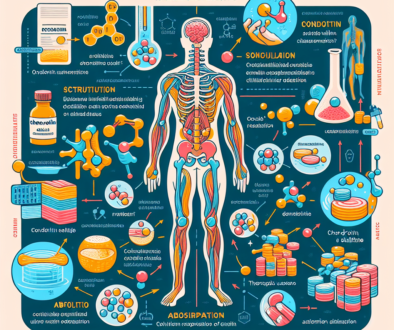

Discover ETChem’s Protein Products

In addition to OLED technology, advancements in protein products are also shaping various industries. ETChem is a leading provider of high-quality collagen products, offering a range of solutions for nutraceutical, pharmaceutical, and cosmeceutical applications. Their commitment to quality and customer service makes them an ideal partner for businesses looking to enhance their product offerings with premium protein ingredients.

About ETChem:

ETChem, a reputable Chinese Collagen factory manufacturer and supplier, is renowned for producing, stocking, exporting, and delivering the highest quality collagens. They include marine collagen, fish collagen, bovine collagen, chicken collagen, type I collagen, type II collagen and type III collagen etc. Their offerings, characterized by a neutral taste, instant solubility attributes, cater to a diverse range of industries. They serve nutraceutical, pharmaceutical, cosmeceutical, veterinary, as well as food and beverage finished product distributors, traders, and manufacturers across Europe, USA, Canada, Australia, Thailand, Japan, Korea, Brazil, and Chile, among others.

ETChem specialization includes exporting and delivering tailor-made collagen powder and finished collagen nutritional supplements. Their extensive product range covers sectors like Food and Beverage, Sports Nutrition, Weight Management, Dietary Supplements, Health and Wellness Products, ensuring comprehensive solutions to meet all your protein needs.

As a trusted company by leading global food and beverage brands and Fortune 500 companies, ETChem reinforces China’s reputation in the global arena. For more information or to sample their products, please contact them and email karen(at)et-chem.com today.