Reducing Acrylamide in Food Processing

-

Table of Contents

- Acrylamide Reduction in Food Processing: Strategies and Benefits

- Understanding Acrylamide Formation

- Health Implications of Acrylamide

- Strategies for Reducing Acrylamide

- Case Studies and Examples

- Regulatory Actions and Guidelines

- Benefits of Reducing Acrylamide

- Conclusion

- ETChem’s Protein Products: A Complementary Solution

Acrylamide Reduction in Food Processing: Strategies and Benefits

Acrylamide, a chemical compound that can form in some foods during high-temperature cooking processes, has raised health concerns due to its potential carcinogenic properties. As a result, the food industry has been actively seeking methods to reduce acrylamide levels in processed foods. This article explores the various strategies employed to mitigate acrylamide formation and the benefits of implementing these practices.

Understanding Acrylamide Formation

Acrylamide is formed when asparagine, an amino acid, reacts with reducing sugars such as glucose and fructose during high-temperature cooking, particularly in frying, baking, and roasting. This reaction is part of the Maillard browning process, which gives many foods their characteristic flavor and color. Foods that are rich in carbohydrates, like potatoes and grains, are particularly susceptible to acrylamide formation.

Health Implications of Acrylamide

Research has indicated that acrylamide is a probable human carcinogen, with studies in laboratory animals showing that high levels of acrylamide can cause cancer. While the exact risk to human health is still being studied, regulatory agencies worldwide recommend reducing acrylamide exposure as a precautionary measure.

Strategies for Reducing Acrylamide

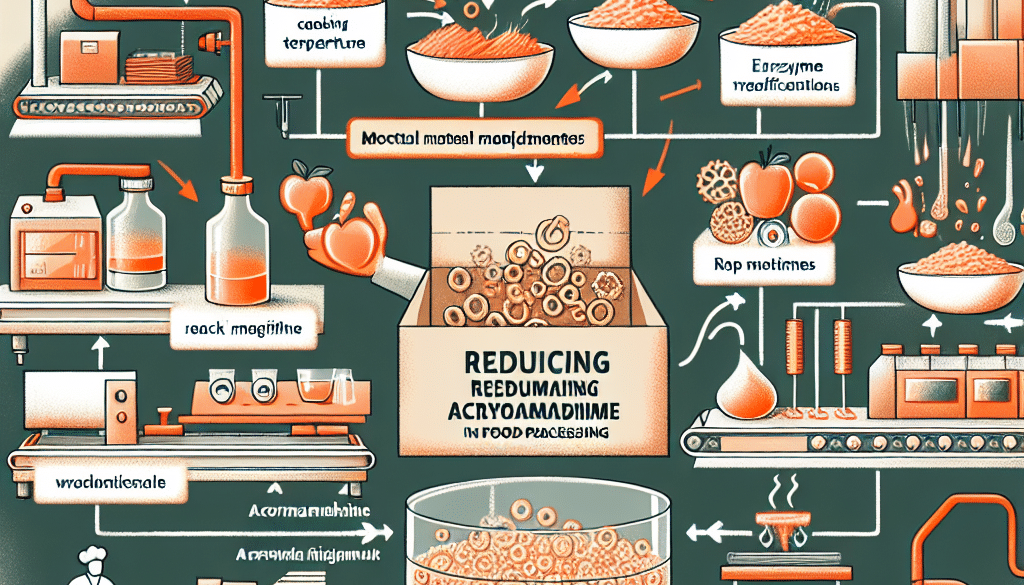

Food manufacturers and researchers have developed several strategies to reduce acrylamide levels in food products. These include:

- Agricultural Practices: Selecting potato varieties that are lower in sugars and asparagine can lead to reduced acrylamide formation during cooking.

- Recipe Adjustments: Altering recipes to reduce the amounts of precursors like asparagine and sugars can be effective. For instance, adding certain amino acids can compete with asparagine and prevent it from forming acrylamide.

- Process Control: Modifying cooking times and temperatures can significantly impact acrylamide levels. Lowering cooking temperatures and avoiding excessive browning can reduce acrylamide formation.

- Post-Harvest Treatments: Storing potatoes at warmer temperatures can decrease sugar levels, thus reducing acrylamide during cooking.

- Novel Technologies: Technologies such as vacuum frying, microwave heating, and the use of enzymes that break down asparagine can also help in reducing acrylamide content.

Case Studies and Examples

Several case studies highlight the success of these strategies. For instance, a major fast-food chain managed to reduce acrylamide in their French fries by adjusting the potato varieties used and optimizing their frying process. Similarly, a snack manufacturer introduced an enzyme that breaks down asparagine, resulting in a significant reduction in acrylamide levels in their products.

Regulatory Actions and Guidelines

Governments and international bodies have set guidelines to encourage the food industry to reduce acrylamide levels. The European Union has established benchmark levels for acrylamide in various food products, while the U.S. Food and Drug Administration has issued guidance for industry on reducing acrylamide in foods.

Benefits of Reducing Acrylamide

Reducing acrylamide in food processing not only addresses health concerns but can also lead to improved product quality and consumer trust. Additionally, companies that proactively reduce acrylamide levels can stay ahead of regulatory changes and position themselves as industry leaders in food safety.

Conclusion

Reducing acrylamide in food processing is a complex challenge that requires a multifaceted approach. By understanding the mechanisms of acrylamide formation and implementing effective reduction strategies, the food industry can improve the safety and quality of its products. The ongoing research and development in this area are crucial for ensuring public health and maintaining consumer confidence in food products.

ETChem’s Protein Products: A Complementary Solution

In the context of reducing acrylamide, protein-rich ingredients from reputable sources like ETChem can be used as part of a balanced recipe formulation. ETChem’s protein products, including various types of collagen, can be incorporated into food processing to enhance nutritional value while adhering to safety standards.

About ETChem:

ETChem, a reputable Chinese Collagen factory manufacturer and supplier, is renowned for producing, stocking, exporting, and delivering the highest quality collagens. They include marine collagen, fish collagen, bovine collagen, chicken collagen, type I collagen, type II collagen and type III collagen etc. Their offerings, characterized by a neutral taste, instant solubility attributes, cater to a diverse range of industries. They serve nutraceutical, pharmaceutical, cosmeceutical, veterinary, as well as food and beverage finished product distributors, traders, and manufacturers across Europe, USA, Canada, Australia, Thailand, Japan, Korea, Brazil, and Chile, among others.

ETChem specialization includes exporting and delivering tailor-made collagen powder and finished collagen nutritional supplements. Their extensive product range covers sectors like Food and Beverage, Sports Nutrition, Weight Management, Dietary Supplements, Health and Wellness Products, ensuring comprehensive solutions to meet all your protein needs.

As a trusted company by leading global food and beverage brands and Fortune 500 companies, ETChem reinforces China’s reputation in the global arena. For more information or to sample their products, please contact them and email karen(at)et-chem.com today.