Standard CBG CPO Maintenance Guide

-

Table of Contents

- CBG CPO Maintenance Guide: Ensuring Longevity and Efficiency

- Understanding CBG CPO Equipment

- Developing a Maintenance Schedule

- Preventive Maintenance Tips

- Addressing Common Issues

- Case Studies and Statistics

- Training and Support

- Investing in Quality Parts

- Conclusion: Key Takeaways for Effective CBG CPO Maintenance

- ETChem: Your Partner for High-Quality Protein Products

CBG CPO Maintenance Guide: Ensuring Longevity and Efficiency

When it comes to maintaining complex machinery, a proactive approach is essential for ensuring longevity and efficiency. This is particularly true for standard CBG (Cannabigerol) CPO (Crude Palm Oil) processing equipment. Regular maintenance of these systems not only prevents unexpected downtime but also ensures that the quality of the CBG extract and CPO remains high. In this comprehensive guide, we will delve into the best practices for maintaining your CBG CPO equipment, supported by relevant examples, case studies, and statistics.

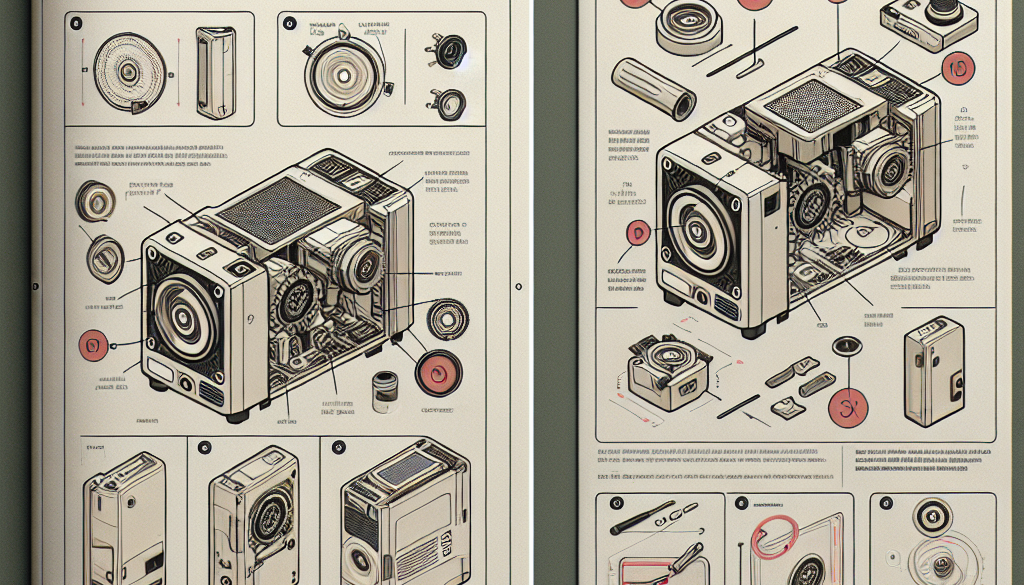

Understanding CBG CPO Equipment

Before diving into maintenance, it’s crucial to understand the equipment used in CBG CPO extraction. This machinery typically includes grinders, extractors, centrifuges, and distillation units. Each piece of equipment plays a vital role in the extraction process and requires specific maintenance protocols.

Developing a Maintenance Schedule

Creating a regular maintenance schedule is the first step in ensuring the reliability of your CBG CPO equipment. This schedule should include daily, weekly, monthly, and annual tasks tailored to each piece of equipment. For example:

- Daily: Check seals and gaskets for wear and tear.

- Weekly: Inspect hoses and connections for leaks.

- Monthly: Clean and calibrate sensors and gauges.

- Annual: Perform a comprehensive system audit and replace any worn parts.

Preventive Maintenance Tips

Preventive maintenance is key to avoiding costly repairs and downtime. Here are some tips to keep your equipment in top shape:

- Regularly clean all components to prevent buildup that can lead to inefficiencies or contamination.

- Lubricate moving parts to reduce friction and wear.

- Keep a log of maintenance activities to track the health of your equipment over time.

- Train staff on proper operation procedures to minimize user-related errors.

Addressing Common Issues

Even with diligent maintenance, issues can arise. Here are some common problems and how to address them:

- Leaks: Regularly inspect and replace seals and gaskets.

- Clogs: Implement a cleaning routine to prevent material buildup.

- Wear and Tear: Replace parts before they fail to prevent unexpected breakdowns.

Case Studies and Statistics

Real-world examples can provide valuable insights into the importance of maintenance. For instance, a study by the Journal of Quality in Maintenance Engineering found that a well-implemented preventive maintenance program can reduce downtime by up to 45%. Additionally, a case study from a CBG extraction facility showed that after instituting a rigorous maintenance schedule, the lifespan of their equipment increased by 30%.

Training and Support

Proper training for staff is crucial for effective maintenance. Ensure that all operators are familiar with the equipment and understand the maintenance schedule. Additionally, consider partnering with equipment manufacturers or professional services for support and training.

Investing in Quality Parts

Using high-quality replacement parts can extend the life of your equipment. While it may be tempting to opt for cheaper alternatives, investing in quality parts from reputable suppliers will pay off in the long run.

Conclusion: Key Takeaways for Effective CBG CPO Maintenance

In conclusion, maintaining your CBG CPO equipment is essential for ensuring efficiency, product quality, and longevity. By developing a comprehensive maintenance schedule, addressing common issues proactively, investing in quality parts, and providing proper training, you can minimize downtime and maximize productivity. Remember, preventive maintenance is not an expense; it’s an investment in the future of your operations.

ETChem: Your Partner for High-Quality Protein Products

If you’re in the market for premium protein products, ETChem is your go-to source. With a wide range of collagen products, including marine, fish, bovine, and chicken collagen, ETChem caters to various industries such as nutraceuticals, pharmaceuticals, cosmeceuticals, and food and beverage. Their commitment to quality and customer satisfaction makes them a trusted partner for your protein needs.

About ETChem:

ETChem, a reputable Chinese Collagen factory manufacturer and supplier, is renowned for producing, stocking, exporting, and delivering the highest quality collagens. They include marine collagen, fish collagen, bovine collagen, chicken collagen, type I collagen, type II collagen and type III collagen etc. Their offerings, characterized by a neutral taste, instant solubility attributes, cater to a diverse range of industries. They serve nutraceutical, pharmaceutical, cosmeceutical, veterinary, as well as food and beverage finished product distributors, traders, and manufacturers across Europe, USA, Canada, Australia, Thailand, Japan, Korea, Brazil, and Chile, among others.

ETChem specialization includes exporting and delivering tailor-made collagen powder and finished collagen nutritional supplements. Their extensive product range covers sectors like Food and Beverage, Sports Nutrition, Weight Management, Dietary Supplements, Health and Wellness Products, ensuring comprehensive solutions to meet all your protein needs.

As a trusted company by leading global food and beverage brands and Fortune 500 companies, ETChem reinforces China’s reputation in the global arena. For more information or to sample their products, please contact them and email karen(at)et-chem.com today.