What Temperature Does Collagen Break Down? Cooking Science

-

Table of Contents

- Cooking Science: Understanding Collagen Breakdown Temperatures

- The Science of Collagen in Cooking

- Collagen Breakdown: The Temperature Threshold

- Factors Affecting Collagen Breakdown

- Practical Applications in Cooking

- Case Studies and Examples

- Conclusion: Key Takeaways on Collagen and Cooking

- Discover ETChem’s Premium Protein Products

Cooking Science: Understanding Collagen Breakdown Temperatures

Collagen is a protein that plays a crucial role in the structure and integrity of various tissues within the body, including skin, bones, and connective tissues. In the culinary world, collagen’s behavior during cooking is of particular interest, as it greatly influences the texture and tenderness of meat. Understanding the temperature at which collagen breaks down can help chefs and home cooks alike to prepare succulent, flavorful dishes. This article delves into the science behind collagen breakdown, offering insights into how temperature affects this process and how it can be harnessed to enhance your cooking.

The Science of Collagen in Cooking

Collagen is the most abundant protein in the animal kingdom, and it’s what gives meat its structure. When it comes to cooking, collagen’s response to heat is a defining factor in the tenderness of the meat. As heat is applied, collagen undergoes a transformation that can either result in tough, chewy meat or a tender, juicy dish.

Collagen Breakdown: The Temperature Threshold

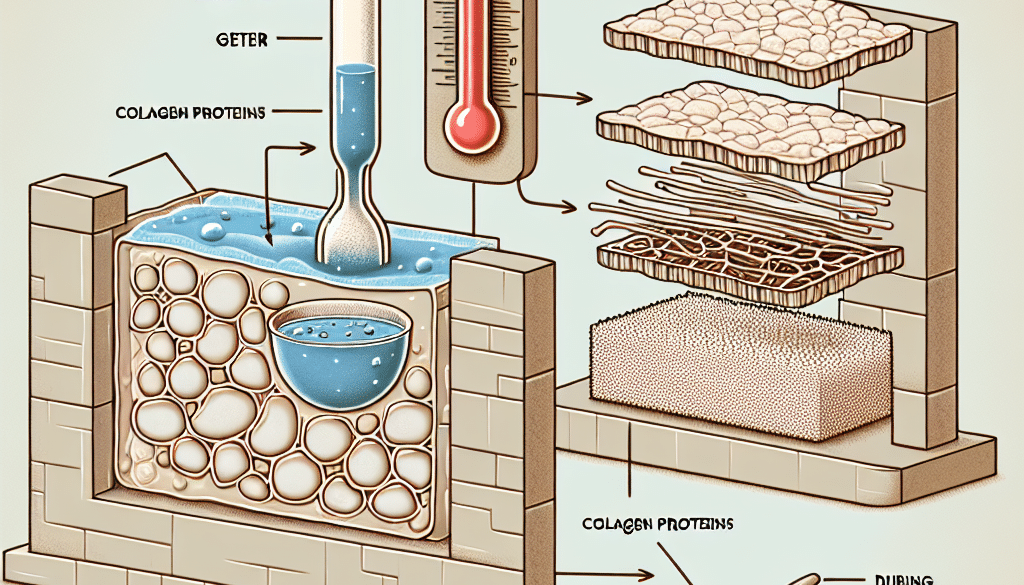

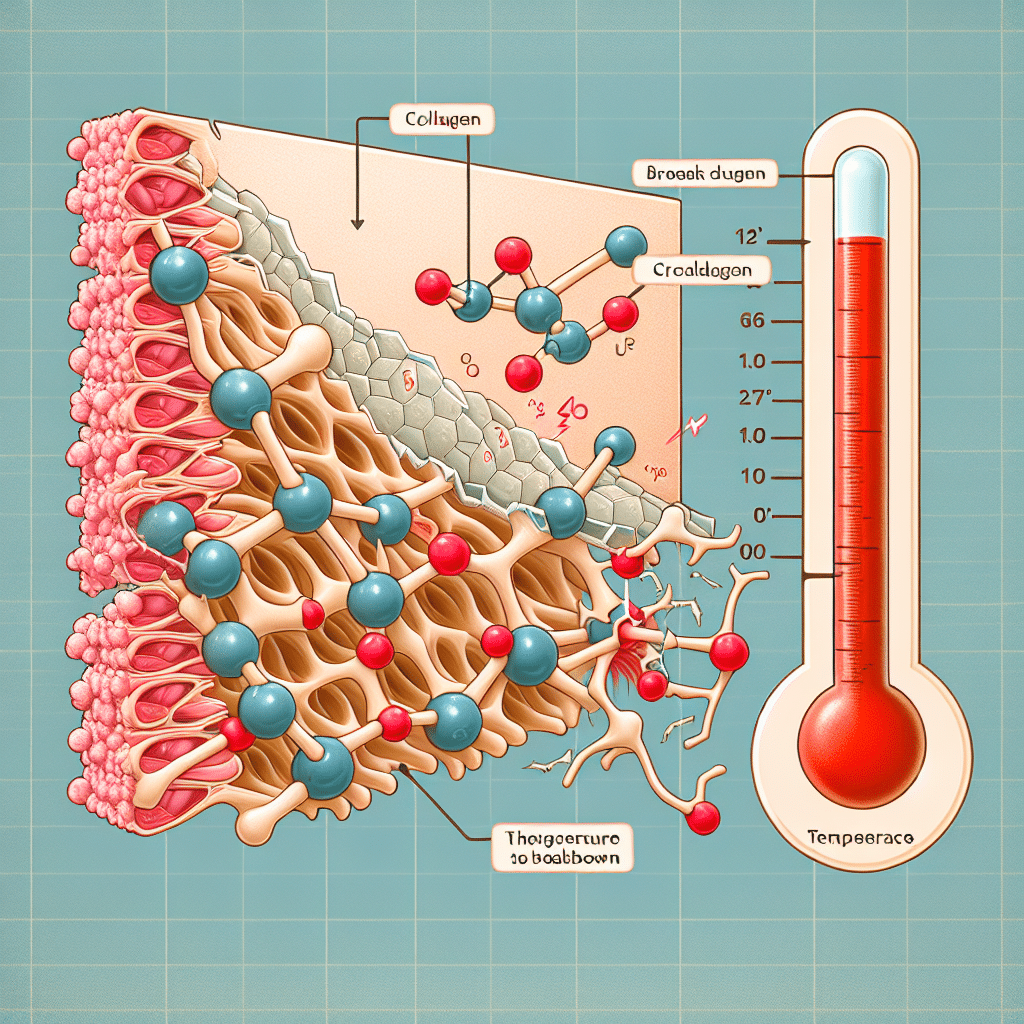

Collagen begins to denature and transform into gelatin at temperatures around 160°F (71°C). However, this is not an instantaneous process. The breakdown of collagen into gelatin occurs over time and is influenced by several factors, including the type of meat, the amount of collagen present, and the cooking method used.

- Slow Cooking: Slow, prolonged cooking at lower temperatures allows collagen to break down more completely, resulting in tender meat.

- Moist Heat: Cooking methods that involve moist heat, such as braising or stewing, are more effective at breaking down collagen than dry-heat methods like roasting or grilling.

- Acidic Environment: The presence of acids, such as vinegar or tomatoes, can also facilitate the breakdown of collagen.

Factors Affecting Collagen Breakdown

While temperature is a key player in collagen breakdown, other factors can influence the process:

- Type of Collagen: There are different types of collagen, and some are more resistant to heat than others. For example, type I collagen, found in tendons, is tougher than type III collagen, found in more delicate tissues.

- Age of the Animal: Older animals tend to have more cross-linked collagen, making their meat tougher and requiring longer cooking times to break down the collagen.

- Cut of Meat: Cuts with more connective tissue, like brisket or shank, have more collagen and thus require longer cooking times to become tender.

Practical Applications in Cooking

Understanding the temperature at which collagen breaks down is invaluable when preparing meat. Here are some practical applications:

- Braising: This technique involves cooking meat slowly in a liquid at low temperatures, which is ideal for breaking down collagen in tougher cuts.

- Sous Vide: Cooking sous vide allows for precise temperature control, ensuring that collagen breaks down without overcooking the meat.

- Pressure Cooking: A pressure cooker can significantly speed up the breakdown of collagen due to the high temperatures and pressure involved.

Case Studies and Examples

Several studies have examined the effects of cooking on collagen. For instance, research has shown that the prolonged cooking of beef brisket at low temperatures can result in a more tender and palatable dish. Similarly, sous vide cooking has been demonstrated to produce consistently tender results by maintaining the optimal temperature for collagen breakdown over an extended period.

Conclusion: Key Takeaways on Collagen and Cooking

In summary, collagen breakdown is a critical aspect of cooking science that can make or break the texture of meat dishes. The key takeaways include:

- Collagen begins to transform into gelatin at around 160°F (71°C).

- Slow, moist cooking methods are best for breaking down collagen.

- The type of collagen, age of the animal, and cut of meat all influence how easily collagen breaks down.

By understanding and applying these principles, cooks can achieve the perfect balance of tenderness and flavor in their meat dishes.

Discover ETChem’s Premium Protein Products

If you’re looking to incorporate high-quality collagen into your diet or products, ETChem offers a range of superior collagen solutions. Their extensive selection includes marine collagen, fish collagen, bovine collagen, and more, catering to various industries and applications. With ETChem’s commitment to excellence, you can trust that you’re getting the best protein products on the market.

About ETChem:

ETChem, a reputable Chinese Collagen factory manufacturer and supplier, is renowned for producing, stocking, exporting, and delivering the highest quality collagens. They include marine collagen, fish collagen, bovine collagen, chicken collagen, type I collagen, type II collagen and type III collagen etc. Their offerings, characterized by a neutral taste, instant solubility attributes, cater to a diverse range of industries. They serve nutraceutical, pharmaceutical, cosmeceutical, veterinary, as well as food and beverage finished product distributors, traders, and manufacturers across Europe, USA, Canada, Australia, Thailand, Japan, Korea, Brazil, and Chile, among others.

ETChem specialization includes exporting and delivering tailor-made collagen powder and finished collagen nutritional supplements. Their extensive product range covers sectors like Food and Beverage, Sports Nutrition, Weight Management, Dietary Supplements, Health and Wellness Products, ensuring comprehensive solutions to meet all your protein needs.

As a trusted company by leading global food and beverage brands and Fortune 500 companies, ETChem reinforces China’s reputation in the global arena. For more information or to sample their products, please contact them and email karen(at)et-chem.com today.