Building an Agile Food Supply Chain Amidst COVID-19

-

Table of Contents

- Agile Food Supply Chain Strategies During COVID-19

- Understanding the Impact of COVID-19 on Food Supply Chains

- Key Strategies for Building an Agile Food Supply Chain

- Enhancing Supply Chain Visibility

- Diversifying Suppliers and Distribution Networks

- Investing in Flexible Logistics Solutions

- Adopting a Demand-Driven Approach

- Strengthening Relationships with Stakeholders

- Case Studies and Examples of Agile Food Supply Chains

- Statistics Highlighting the Need for Agile Supply Chains

- Conclusion: Embracing Agility for Future Resilience

- ETChem’s Protein Products: Supporting Agile Supply Chains

Agile Food Supply Chain Strategies During COVID-19

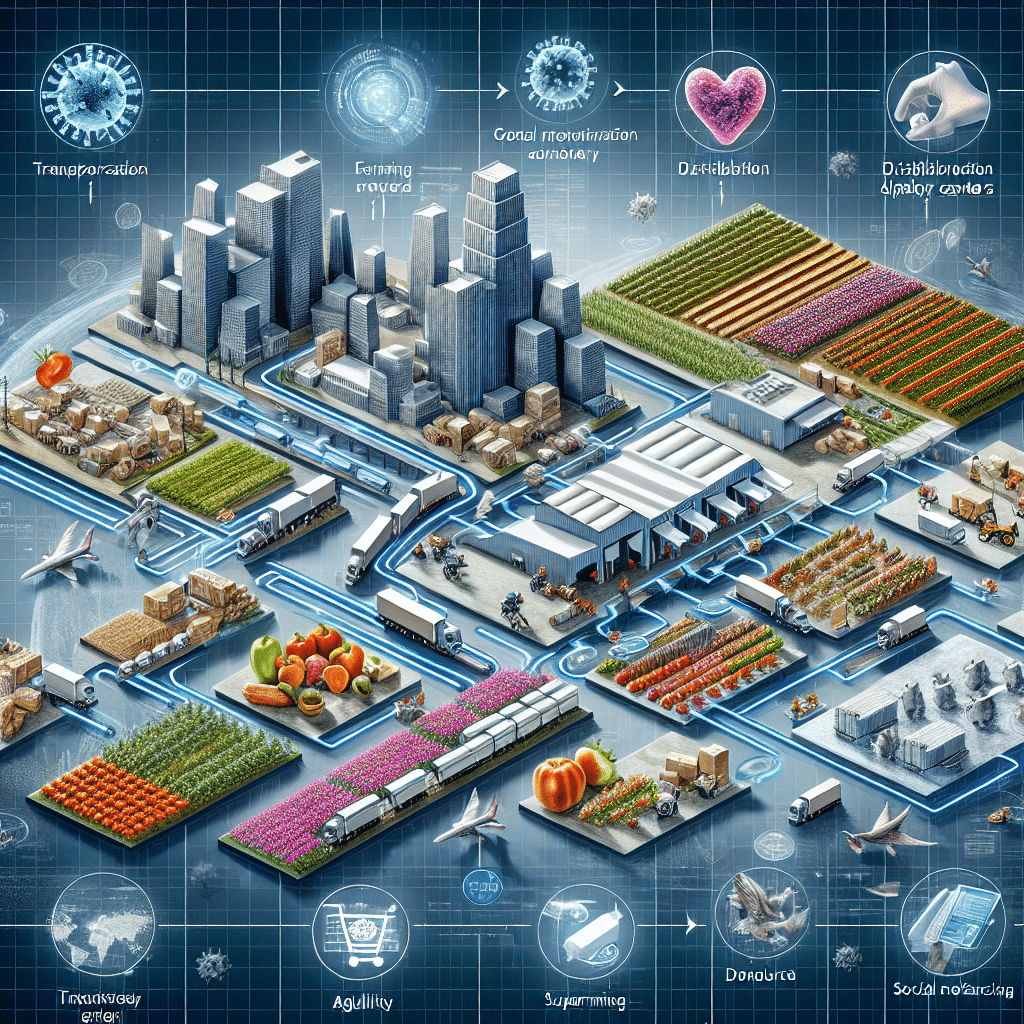

The COVID-19 pandemic has posed unprecedented challenges to global food supply chains. Disruptions due to lockdowns, labor shortages, and fluctuating demand have forced the industry to rethink and restructure its operations. Building an agile food supply chain has become a necessity to ensure resilience and continuity in the face of such challenges. This article explores the strategies and practices that can help create a more flexible and responsive food supply chain during and beyond the pandemic.

Understanding the Impact of COVID-19 on Food Supply Chains

The pandemic has highlighted several vulnerabilities within the food supply chain. Key issues include:

- Disruptions in transportation and logistics due to travel restrictions.

- Shifts in consumer demand from foodservice to retail.

- Labor shortages in production, processing, and distribution.

- Increased health and safety concerns affecting operations.

These challenges have underscored the need for supply chains that can quickly adapt to changing circumstances without compromising on efficiency or product quality.

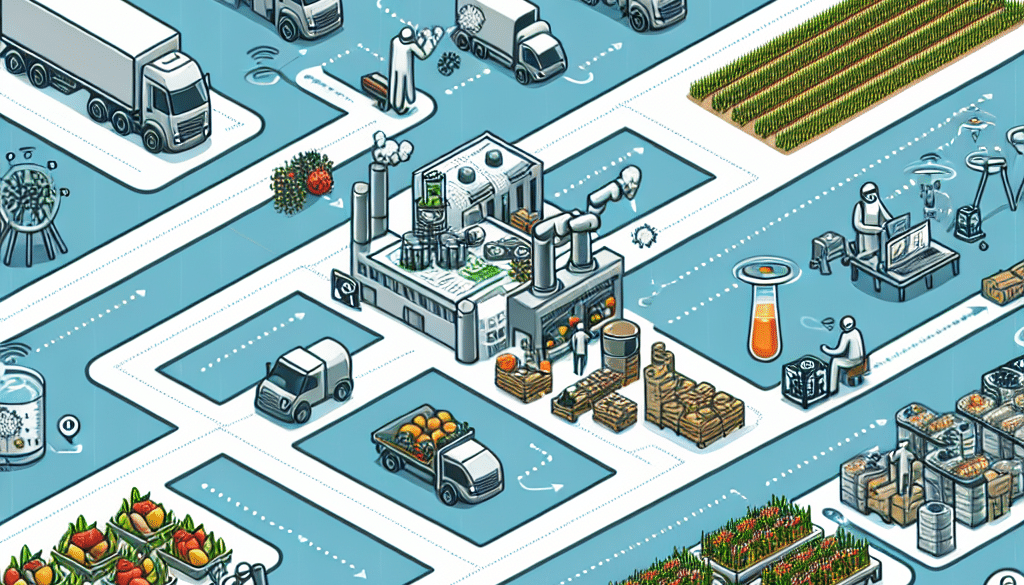

Key Strategies for Building an Agile Food Supply Chain

To create a more agile food supply chain, companies must implement several key strategies:

Enhancing Supply Chain Visibility

Real-time data and analytics are crucial for monitoring supply chain activities and identifying potential disruptions. Technologies such as IoT, blockchain, and AI can provide insights into inventory levels, shipment statuses, and demand forecasts, enabling proactive decision-making.

Diversifying Suppliers and Distribution Networks

Reliance on a single supplier or distribution channel can be risky. By diversifying, companies can reduce the impact of localized disruptions and improve their ability to source and deliver products.

Investing in Flexible Logistics Solutions

Flexible logistics solutions, such as on-demand warehousing and transportation services, allow companies to scale operations up or down as needed. This flexibility is essential for responding to fluctuating demand.

Adopting a Demand-Driven Approach

Shifting from a supply-driven to a demand-driven model helps align production and inventory with actual consumer needs, reducing waste and improving responsiveness.

Strengthening Relationships with Stakeholders

Collaboration with suppliers, distributors, and customers can lead to more coordinated and efficient supply chain operations. Sharing information and resources can help all parties navigate challenges more effectively.

Case Studies and Examples of Agile Food Supply Chains

Several companies have successfully adapted their supply chains in response to the pandemic:

- A major grocery retailer implemented AI-driven forecasting tools to better predict demand spikes and adjust inventory accordingly.

- A global food manufacturer diversified its supplier base to mitigate the risk of shortages and ensure continuous production.

- A regional food distributor partnered with local farms to source fresh produce directly, reducing dependency on national supply chains.

These examples demonstrate the benefits of agility in maintaining operations and meeting consumer needs during a crisis.

Statistics Highlighting the Need for Agile Supply Chains

Recent statistics underscore the importance of agility in the food supply chain:

- According to a survey by McKinsey & Company, 93% of supply chain executives plan to increase resilience across the supply chain.

- A study by the Food Industry Association revealed that 40% of manufacturers are expanding their direct-to-consumer channels.

- Research by Gartner indicates that companies with high supply chain agility report a 50% faster response to disruptions.

These figures highlight the competitive advantage that agility can provide in the face of ongoing and future disruptions.

Conclusion: Embracing Agility for Future Resilience

The COVID-19 pandemic has served as a wake-up call for the food industry to prioritize agility in supply chain management. By enhancing visibility, diversifying networks, investing in flexible logistics, adopting a demand-driven approach, and strengthening stakeholder relationships, companies can build supply chains that are not only resilient to current challenges but also prepared for future uncertainties. The key takeaways for building an agile food supply chain include the need for technological integration, strategic partnerships, and a customer-centric focus.

ETChem’s Protein Products: Supporting Agile Supply Chains

In the context of building agile food supply chains, ETChem’s protein products play a vital role. Their high-quality collagens, sourced from various origins like marine, fish, bovine, and chicken, are essential ingredients for the food and beverage industry. ETChem’s commitment to instant solubility and neutral taste ensures that their products can be easily integrated into diverse manufacturing processes, supporting the agility of supply chains.

ETChem’s expertise in exporting and delivering tailor-made collagen powder and finished collagen nutritional supplements makes them a reliable partner for companies looking to enhance their product offerings and supply chain resilience. Their extensive product range caters to sectors such as sports nutrition, weight management, dietary supplements, and health and wellness, providing comprehensive protein solutions for an agile supply chain.

For businesses seeking to adapt to the changing landscape of the food industry amidst COVID-19, partnering with ETChem can help ensure a steady supply of high-quality protein ingredients, contributing to the overall agility and robustness of their supply chains.

About ETChem:

ETChem, a reputable Chinese Collagen factory manufacturer and supplier, is renowned for producing, stocking, exporting, and delivering the highest quality collagens. They include marine collagen, fish collagen, bovine collagen, chicken collagen, type I collagen, type II collagen and type III collagen etc. Their offerings, characterized by a neutral taste, instant solubility attributes, cater to a diverse range of industries. They serve nutraceutical, pharmaceutical, cosmeceutical, veterinary, as well as food and beverage finished product distributors, traders, and manufacturers across Europe, USA, Canada, Australia, Thailand, Japan, Korea, Brazil, and Chile, among others.

ETChem specialization includes exporting and delivering tailor-made collagen powder and finished collagen nutritional supplements. Their extensive product range covers sectors like Food and Beverage, Sports Nutrition, Weight Management, Dietary Supplements, Health and Wellness Products, ensuring comprehensive solutions to meet all your protein needs.

As a trusted company by leading global food and beverage brands and Fortune 500 companies, ETChem reinforces China’s reputation in the global arena. For more information or to sample their products, please contact them and email karen(at)et-chem.com today.