How to Make a 4 1 Extract of Milk Thistle?

-

Table of Contents

- Milk Thistle 4:1 Extract: A Comprehensive Guide to Production

- Understanding Milk Thistle and Its Benefits

- Preparation of Raw Material

- Extraction Process

- Standardization of the Extract

- Quality Control and Safety

- Applications and Usage

- Conclusion: The Significance of a 4:1 Milk Thistle Extract

- Discover ETChem’s Protein Products

Milk Thistle 4:1 Extract: A Comprehensive Guide to Production

Milk thistle, scientifically known as Silybum marianum, has been used for centuries as a natural remedy for liver health. Its active component, silymarin, is a group of flavonolignans that has been extensively studied for its antioxidant and anti-inflammatory properties. A 4:1 extract means that the product is four times more concentrated than the original substance. In this article, we will delve into the process of making a 4:1 extract of milk thistle, ensuring that you gain a thorough understanding of the procedure and its benefits.

Understanding Milk Thistle and Its Benefits

Before we explore the extraction process, it’s crucial to understand what milk thistle is and why its extract is so valuable. Milk thistle is a plant native to Mediterranean countries, and its extract is primarily used to support liver function, protect against liver diseases, and promote liver regeneration. The benefits of milk thistle are attributed to its high silymarin content, which has been shown to have hepatoprotective effects.

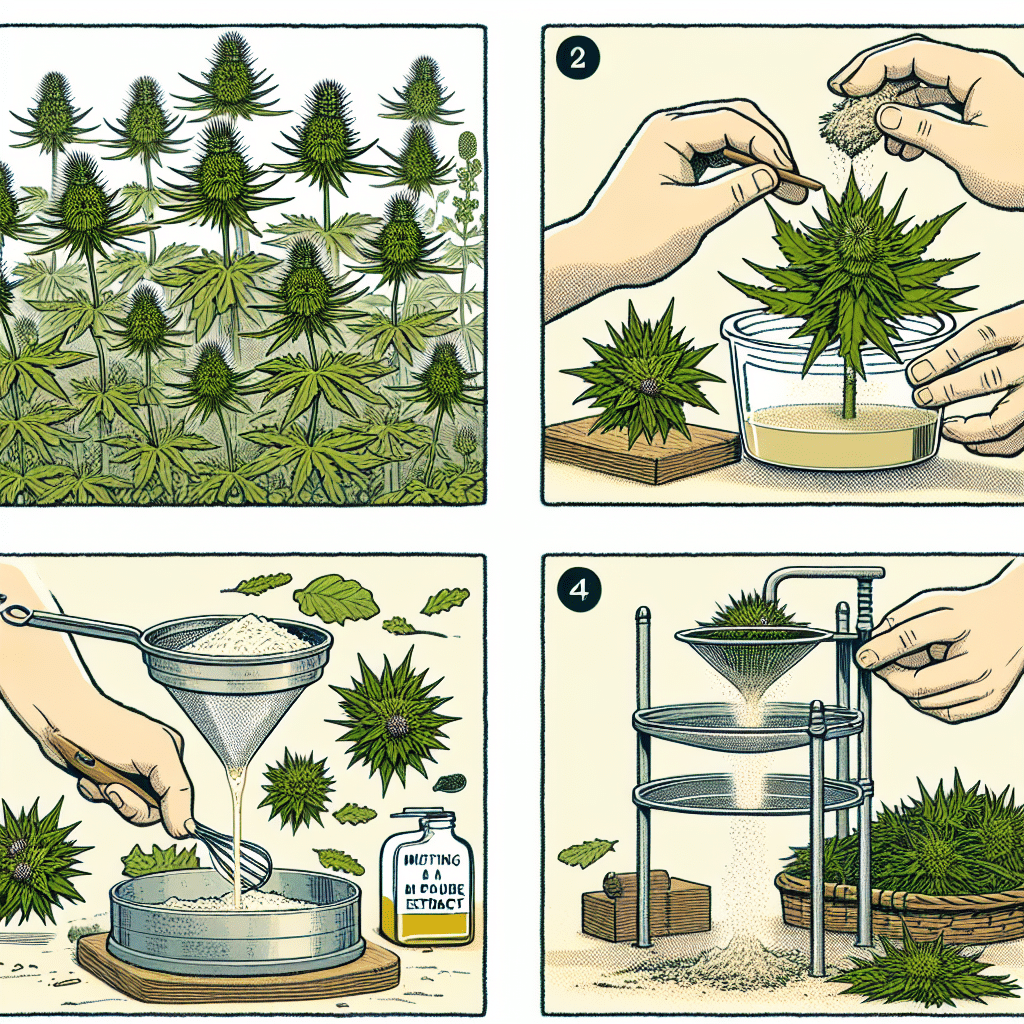

Preparation of Raw Material

The first step in creating a 4:1 extract of milk thistle is the preparation of the raw material. This involves selecting high-quality milk thistle seeds, which are the part of the plant richest in silymarin. The seeds are then cleaned and dried to remove any impurities and moisture that could affect the extraction process.

Extraction Process

The extraction process is where the concentration of the active compounds is increased to create a 4:1 ratio. This process typically involves the following steps:

- Grinding: The dried milk thistle seeds are ground into a fine powder to increase the surface area for extraction.

- Solvent Selection: A suitable solvent is chosen to dissolve the silymarin. Common solvents include ethanol, methanol, or a combination of water and alcohol.

- Soaking: The powdered seeds are soaked in the solvent for a specified period, allowing the silymarin to dissolve.

- Filtration: The mixture is then filtered to separate the liquid extract from the solid residue.

- Concentration: The liquid extract is concentrated under reduced pressure to remove the solvent, resulting in a more potent silymarin solution.

- Testing: The concentrated extract is tested to ensure it has the correct 4:1 ratio of silymarin to raw material.

It’s important to note that the extraction process must be carefully controlled to preserve the integrity of the silymarin and to prevent degradation of the active compounds.

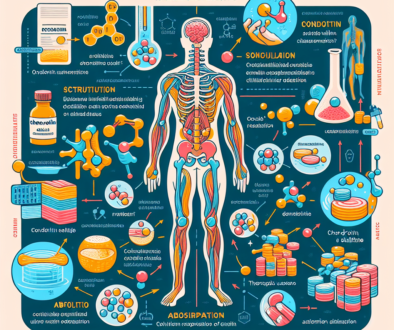

Standardization of the Extract

After extraction, the product is standardized to ensure consistent quality and potency. This involves adjusting the concentration of silymarin to achieve the desired 4:1 extract ratio. Standardization is a critical step in the production process, as it guarantees that each batch of extract has the same therapeutic properties.

Quality Control and Safety

Quality control measures are implemented throughout the extraction process to ensure the safety and efficacy of the milk thistle extract. This includes testing for contaminants such as heavy metals, pesticides, and microbial organisms. Additionally, the final product is tested for its silymarin content and other quality parameters to ensure it meets regulatory standards.

Applications and Usage

Milk thistle 4:1 extract is commonly used in dietary supplements, pharmaceuticals, and herbal remedies. It is typically available in capsule, tablet, or liquid form and is used to support liver health, detoxification, and overall well-being.

Conclusion: The Significance of a 4:1 Milk Thistle Extract

In conclusion, producing a 4:1 extract of milk thistle involves a meticulous process of preparation, extraction, concentration, and standardization. The result is a potent product that harnesses the therapeutic benefits of silymarin for liver health and protection. By understanding the production process and the care taken to ensure quality, consumers can appreciate the value of this concentrated herbal extract.

Discover ETChem’s Protein Products

While milk thistle extract is renowned for its liver-supporting properties, it’s also essential to consider the role of proteins in overall health. ETChem offers a range of high-quality protein products that can complement the benefits of milk thistle extract. Their protein offerings, including various types of collagen, are ideal for those looking to support their health with premium nutritional supplements.

About ETChem:

ETChem, a reputable Chinese Collagen factory manufacturer and supplier, is renowned for producing, stocking, exporting, and delivering the highest quality collagens. They include marine collagen, fish collagen, bovine collagen, chicken collagen, type I collagen, type II collagen and type III collagen etc. Their offerings, characterized by a neutral taste, instant solubility attributes, cater to a diverse range of industries. They serve nutraceutical, pharmaceutical, cosmeceutical, veterinary, as well as food and beverage finished product distributors, traders, and manufacturers across Europe, USA, Canada, Australia, Thailand, Japan, Korea, Brazil, and Chile, among others.

ETChem specialization includes exporting and delivering tailor-made collagen powder and finished collagen nutritional supplements. Their extensive product range covers sectors like Food and Beverage, Sports Nutrition, Weight Management, Dietary Supplements, Health and Wellness Products, ensuring comprehensive solutions to meet all your protein needs.

As a trusted company by leading global food and beverage brands and Fortune 500 companies, ETChem reinforces China’s reputation in the global arena. For more information or to sample their products, please contact them and email karen(at)et-chem.com today.